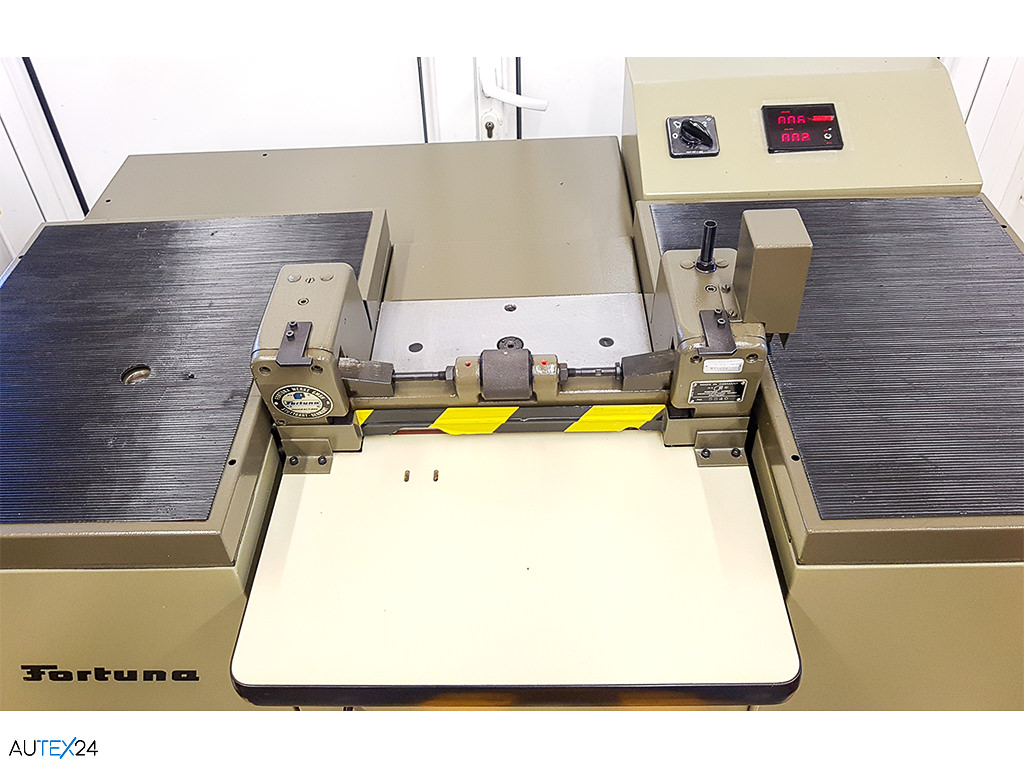

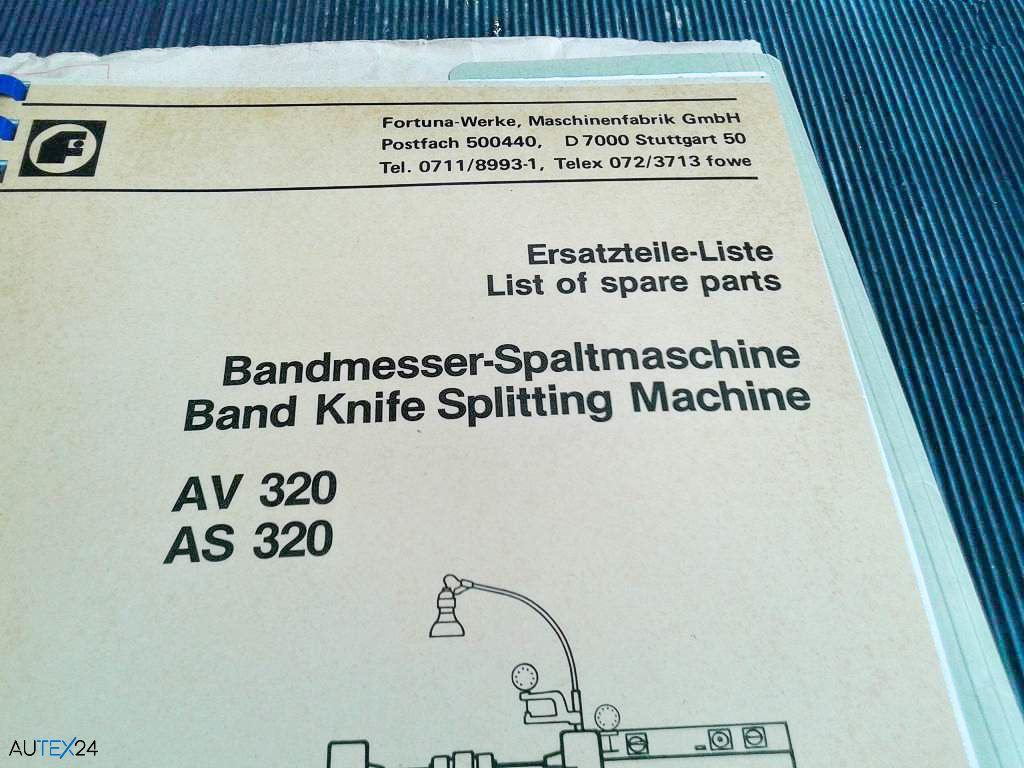

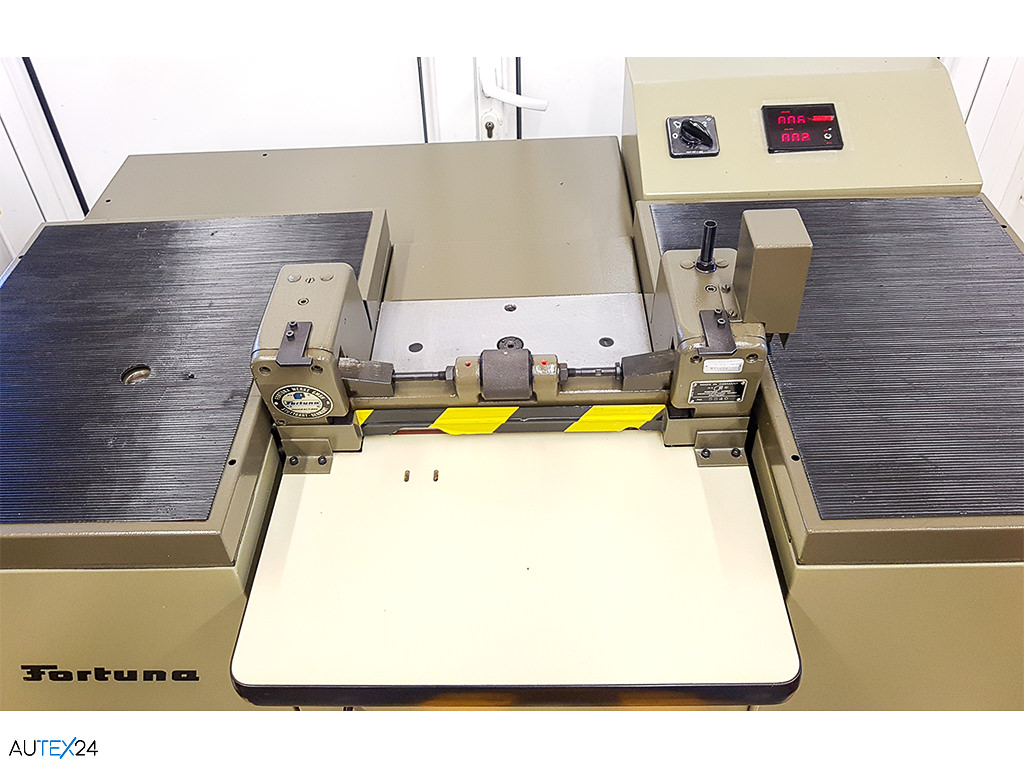

With 320 mm gap width, driven guide roller, lower elastic feed roller, automatic chip and dust extraction, grinding device for the band knife, automatic adjustment and tensioning of the band knife guide and four feed speeds

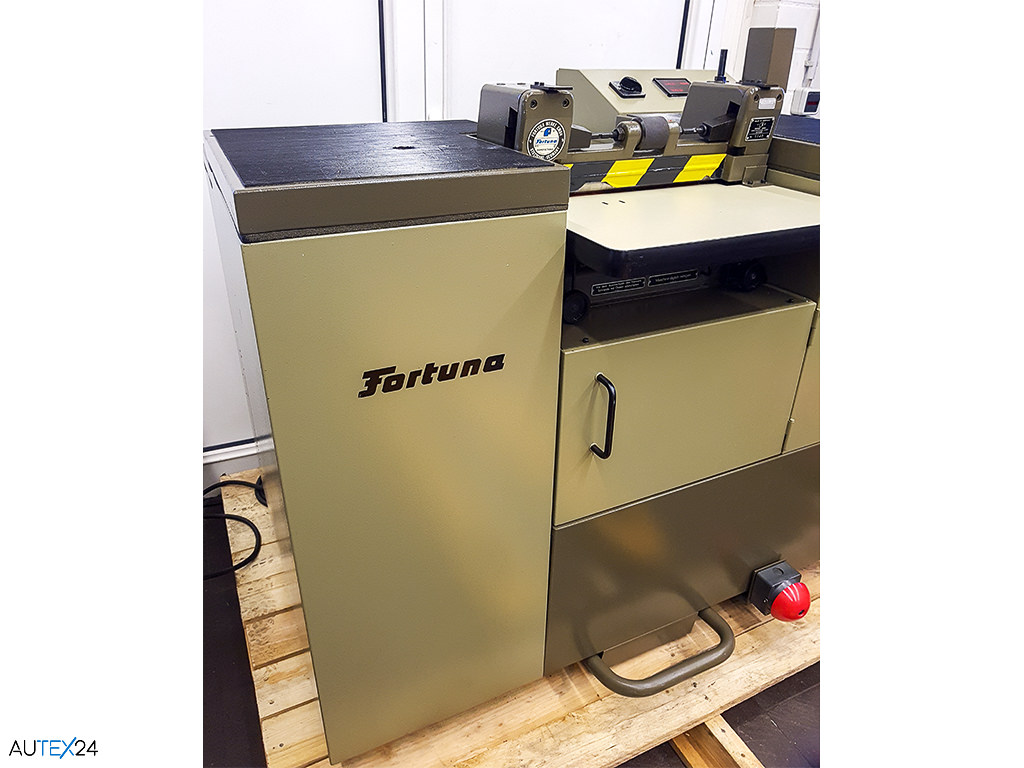

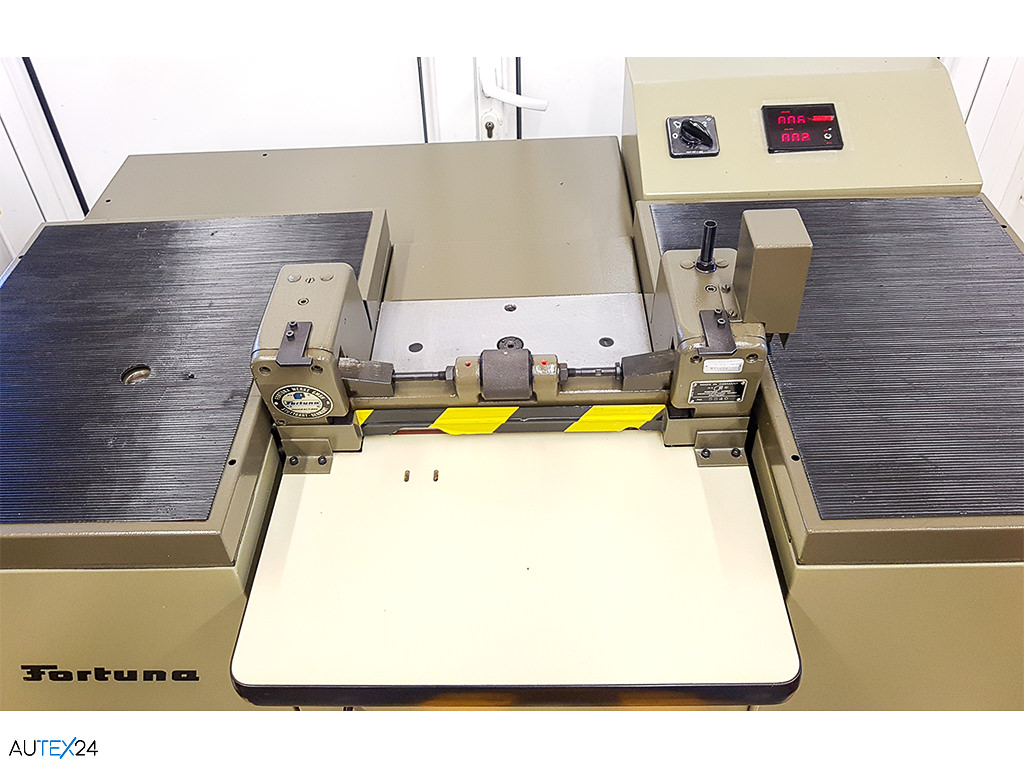

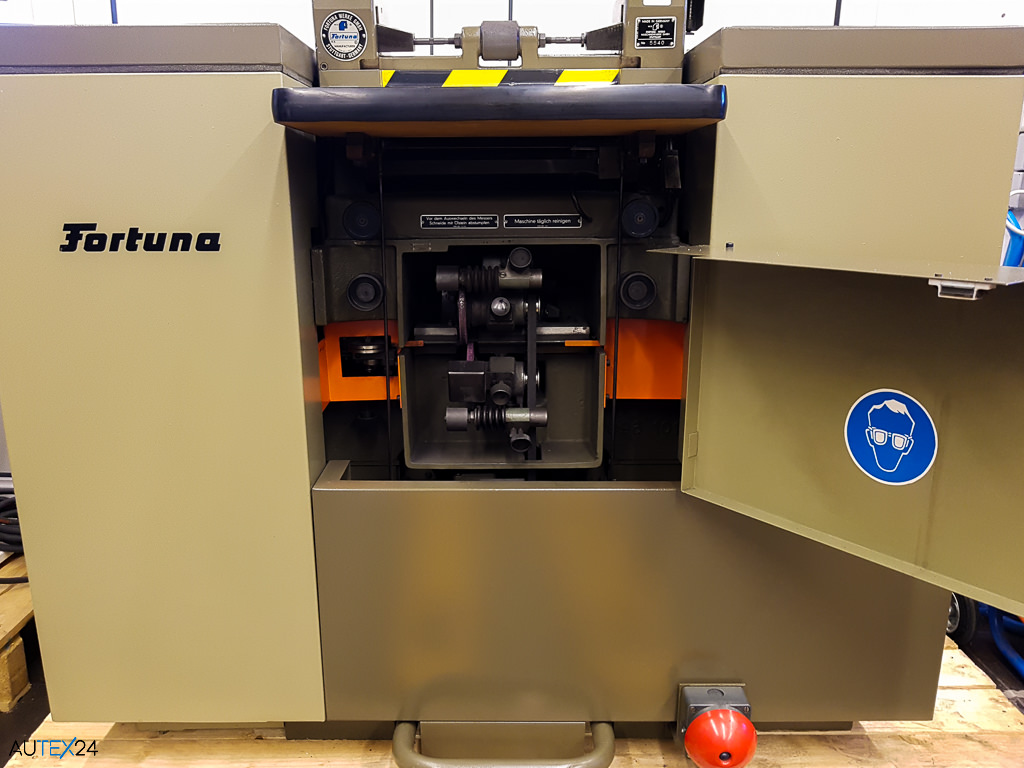

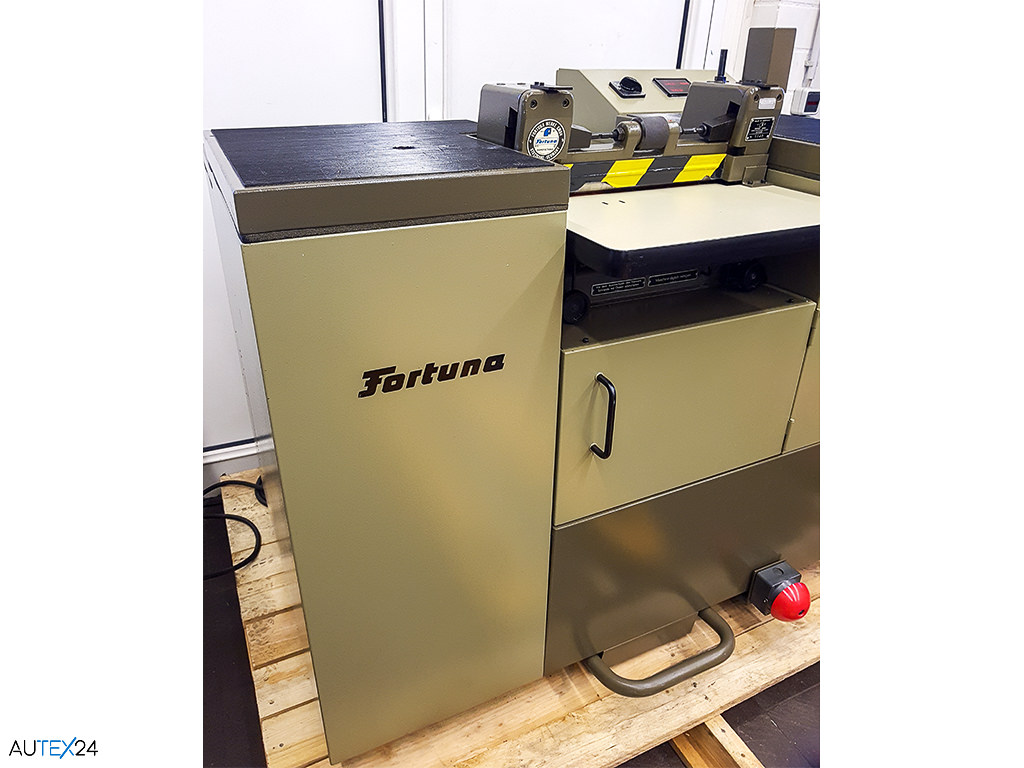

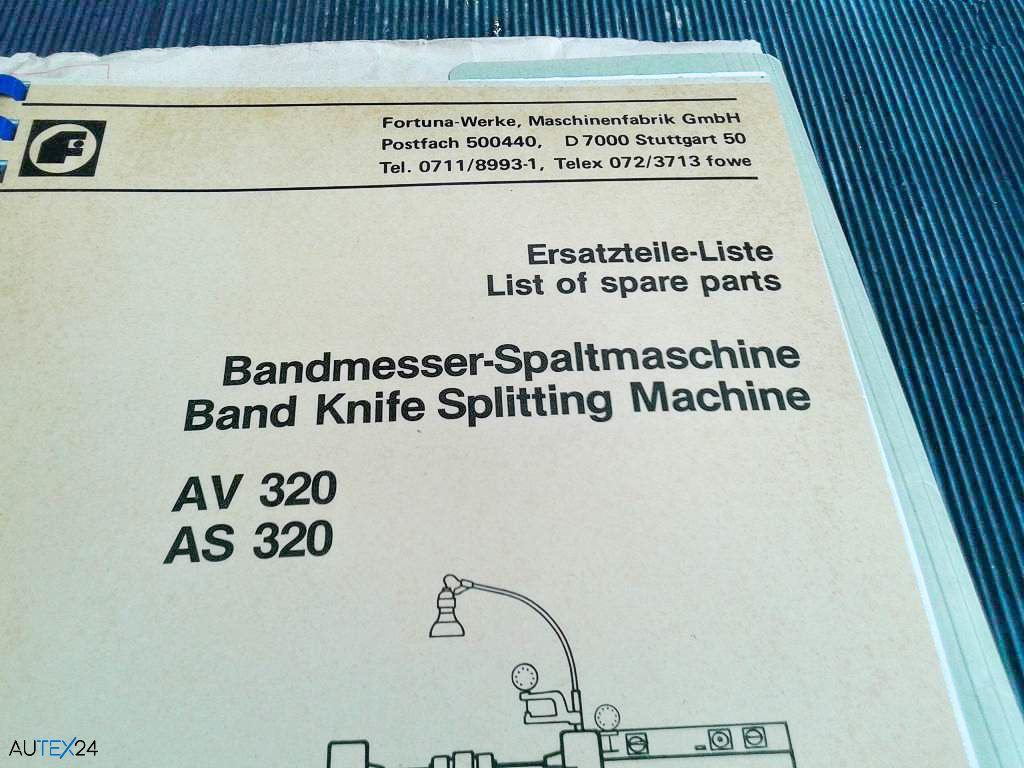

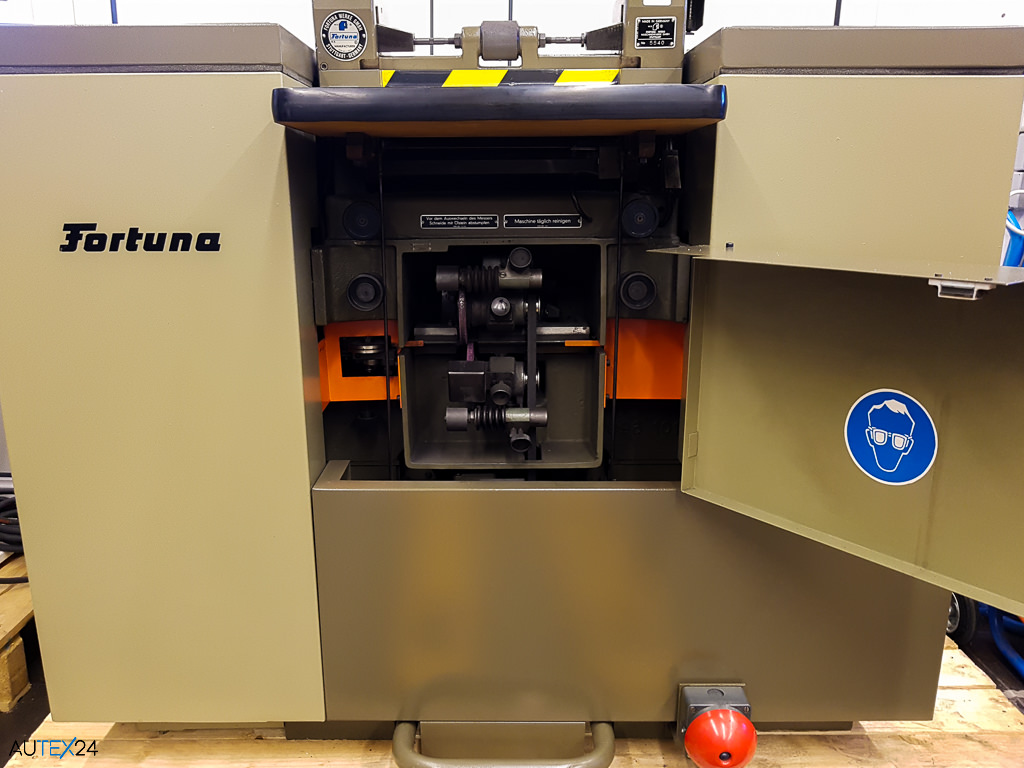

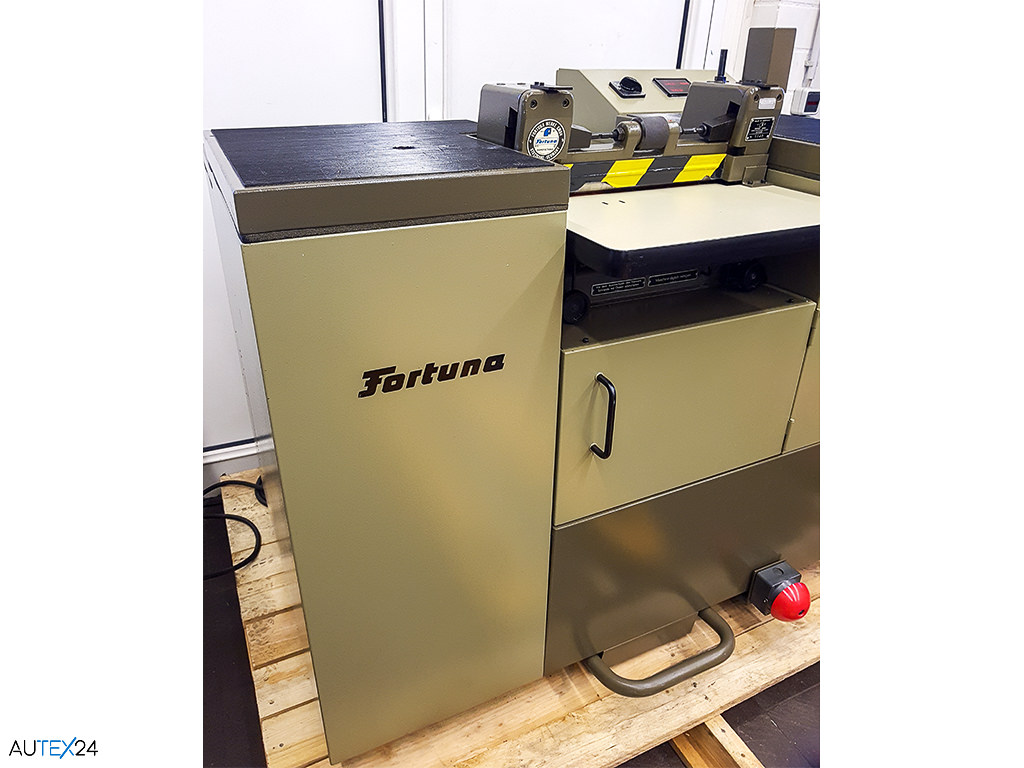

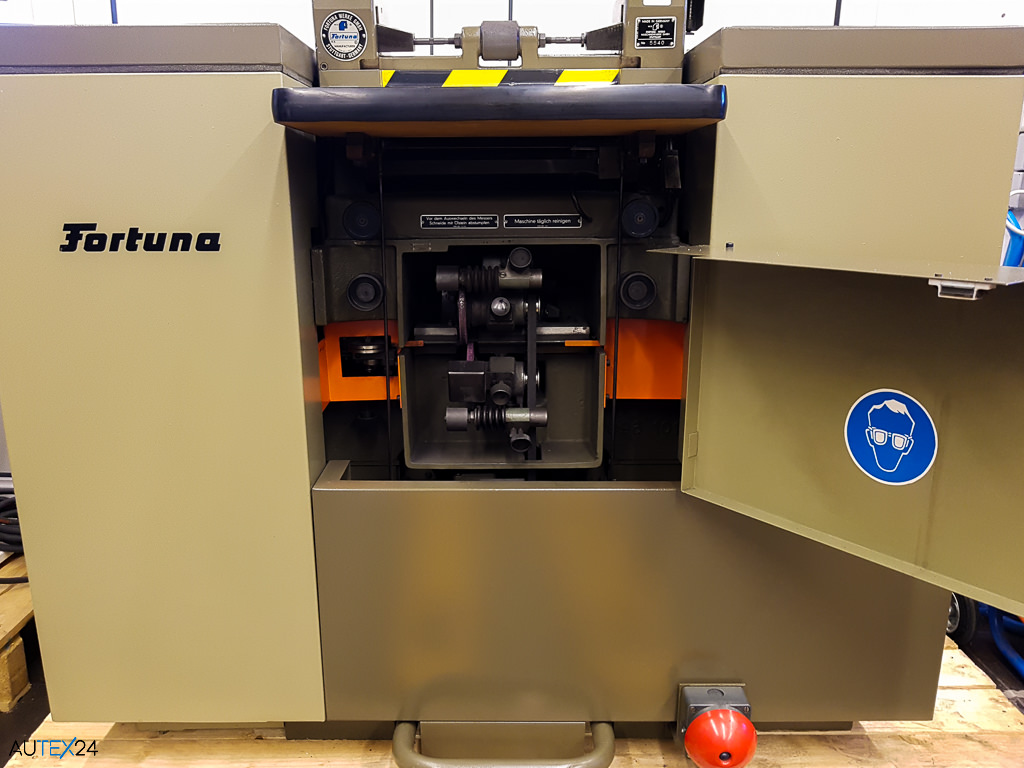

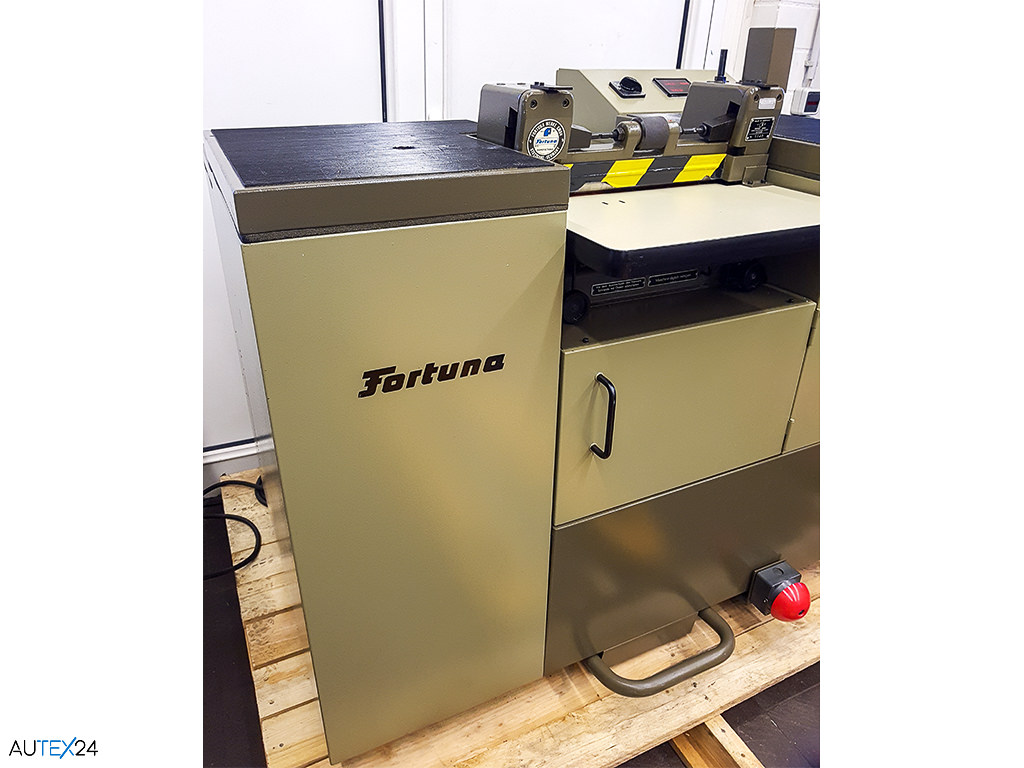

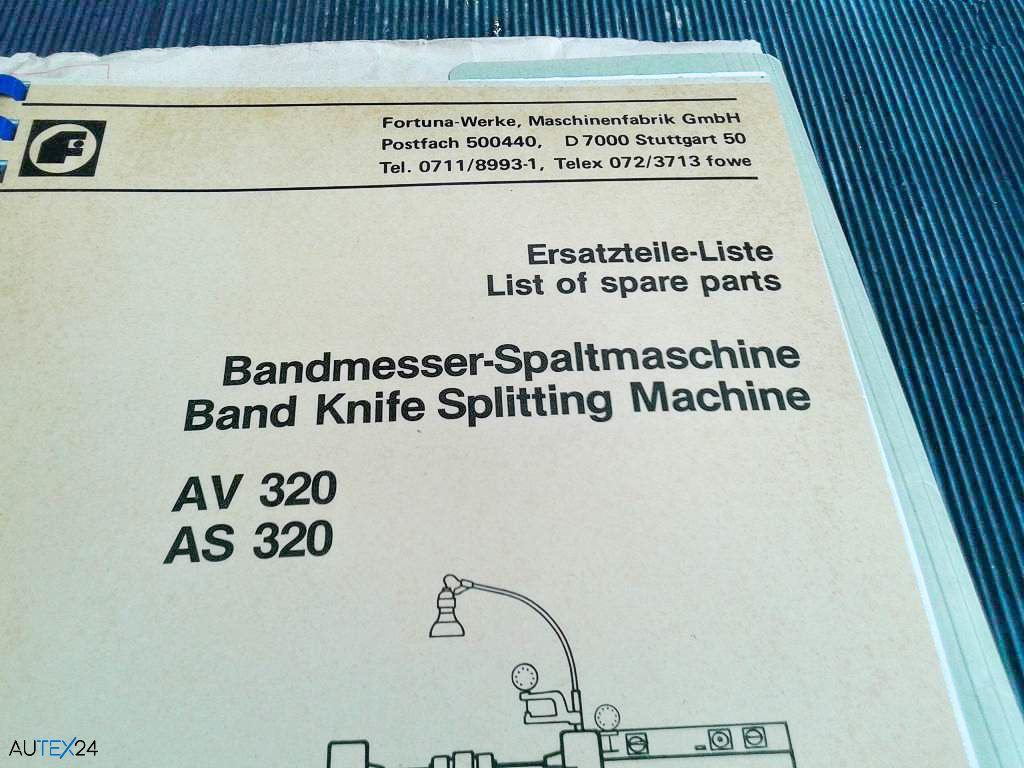

The Fortuna AV 320 leather splitting machine is in good used condition, fully functional, cleaned and ready for immediate use. The optical condition can be seen in the attached pictures and videos. An inspection and detailed examination of the purchased item, is expressly desired by arrangement.

The Fortuna AV 320 leather splitting machine is suitable for splitting leather and similar materials in the footwear and leather goods industry. With its help, materials can be separated into several layers with extreme precision. The leveling of unevenly thick material to a specific thickness or the reduction of a given initial thickness to a specific final dimension can be implemented with it. Equipped with suitable devices and fixtures, it can be used for single-slit, inclined-slit, template-sharpening and profile-sharpening operations.

It is equally suitable for factories of any size. It splits and levels leather of all types, from the finest chevreau, pig, calf, goat, and sheep leather, to the heaviest fat leather. It also easily splits soft and medium cowhide, blank leather, as well as synthetic leather, felt, cork and similar materials.

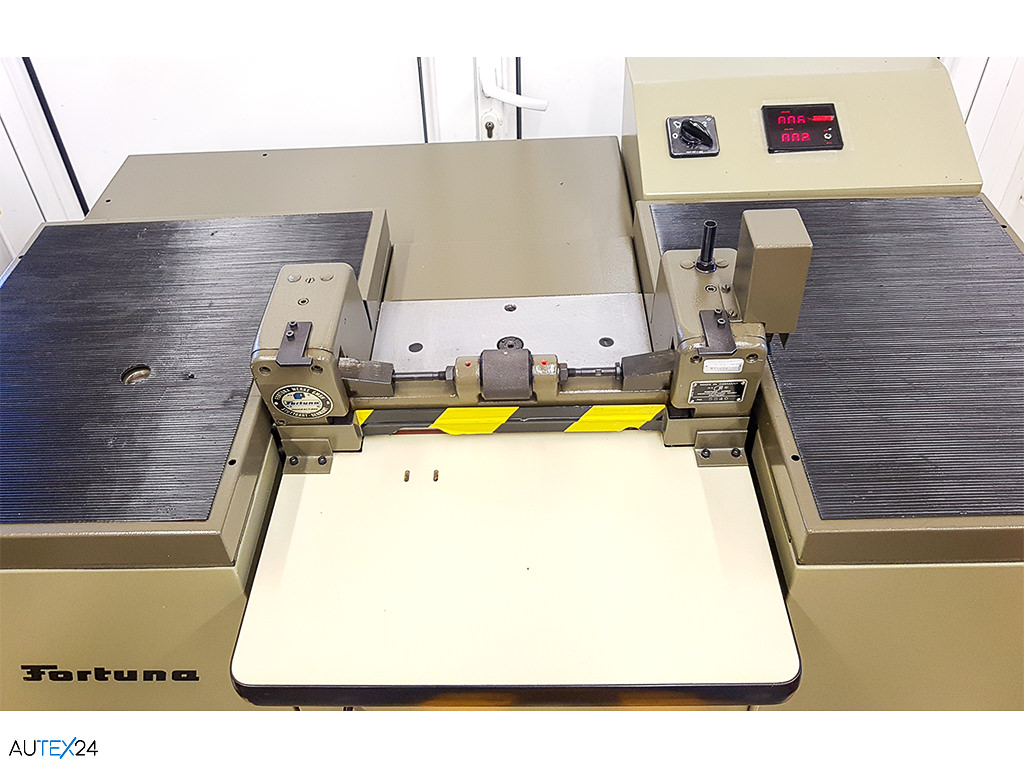

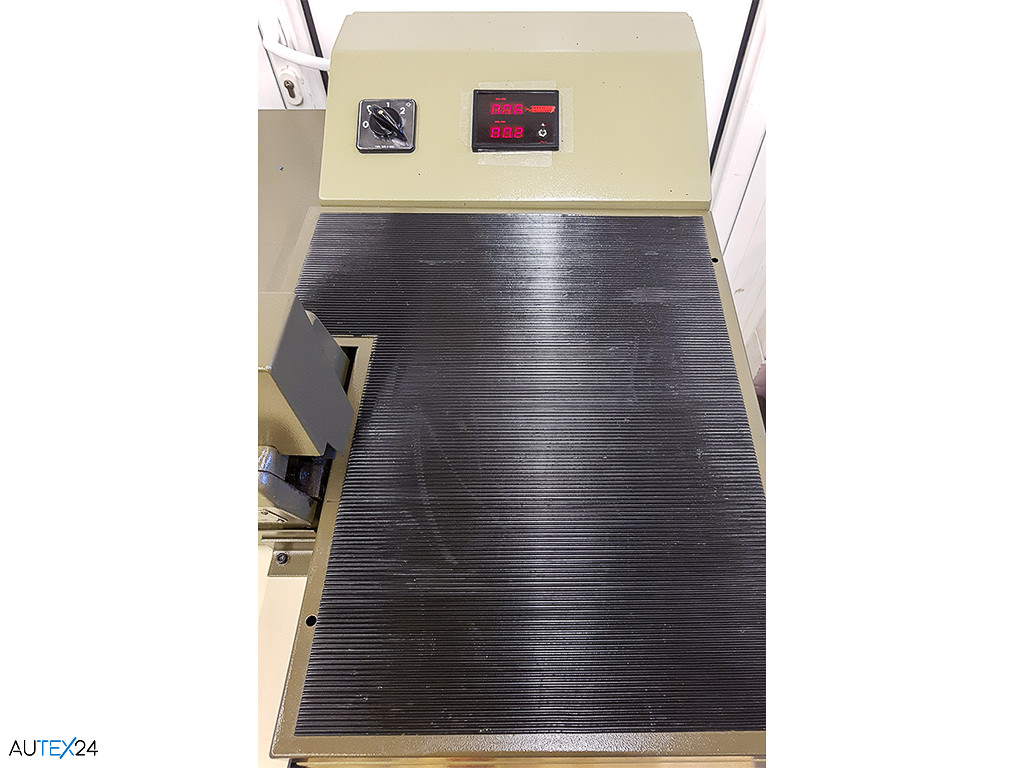

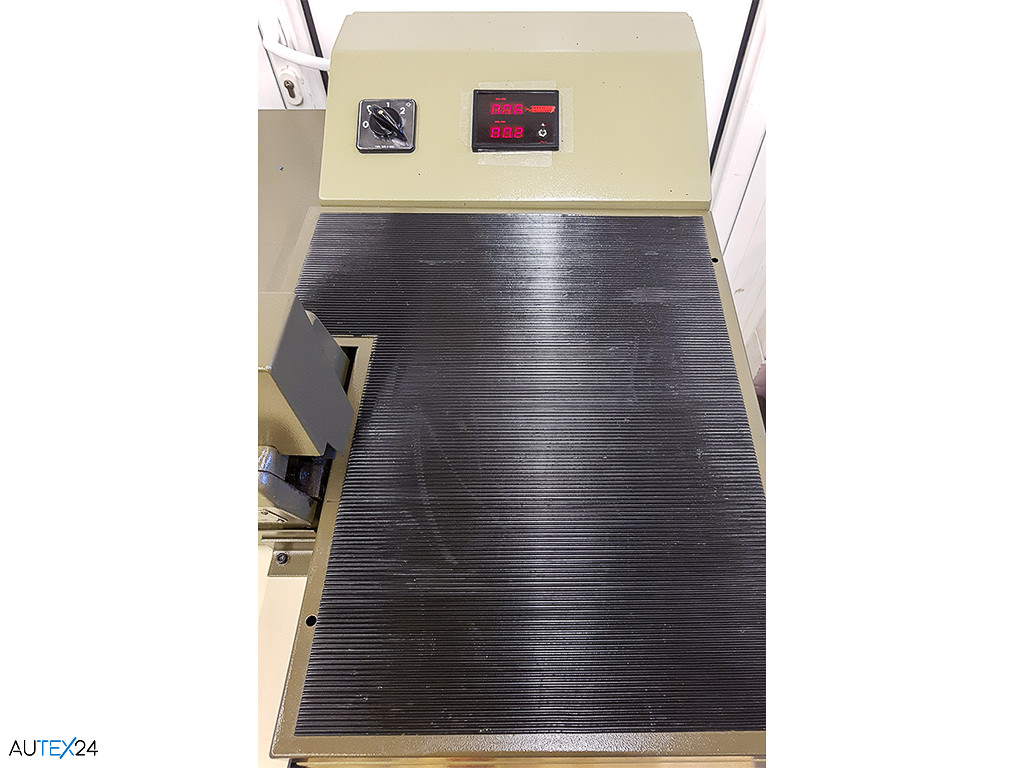

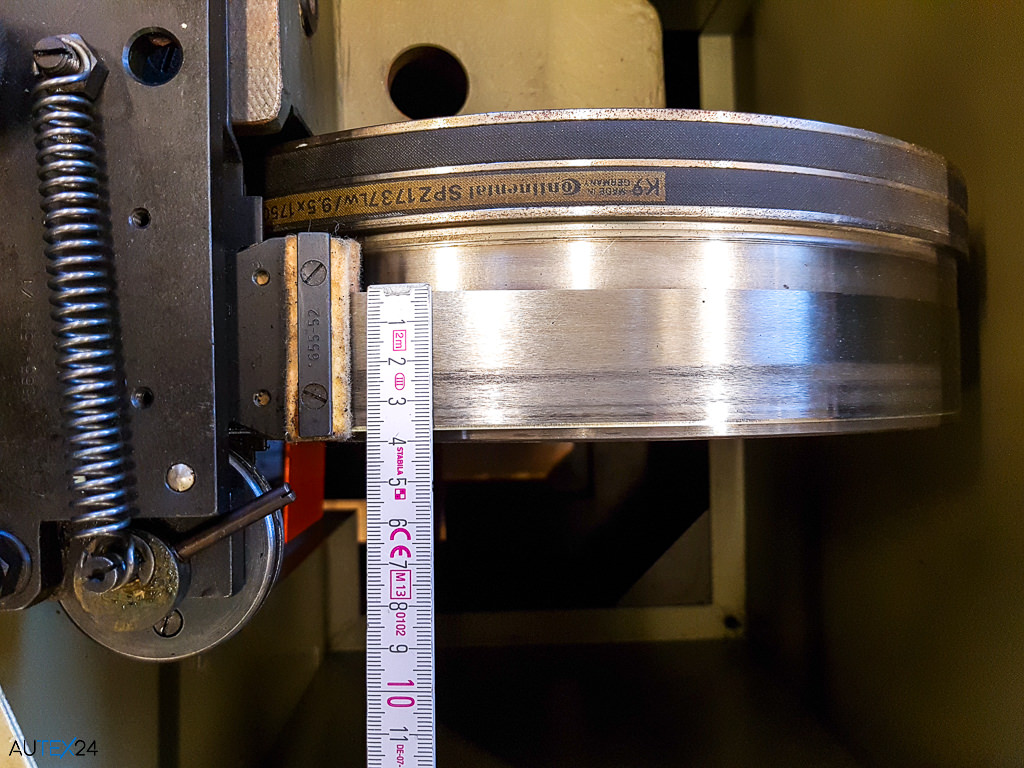

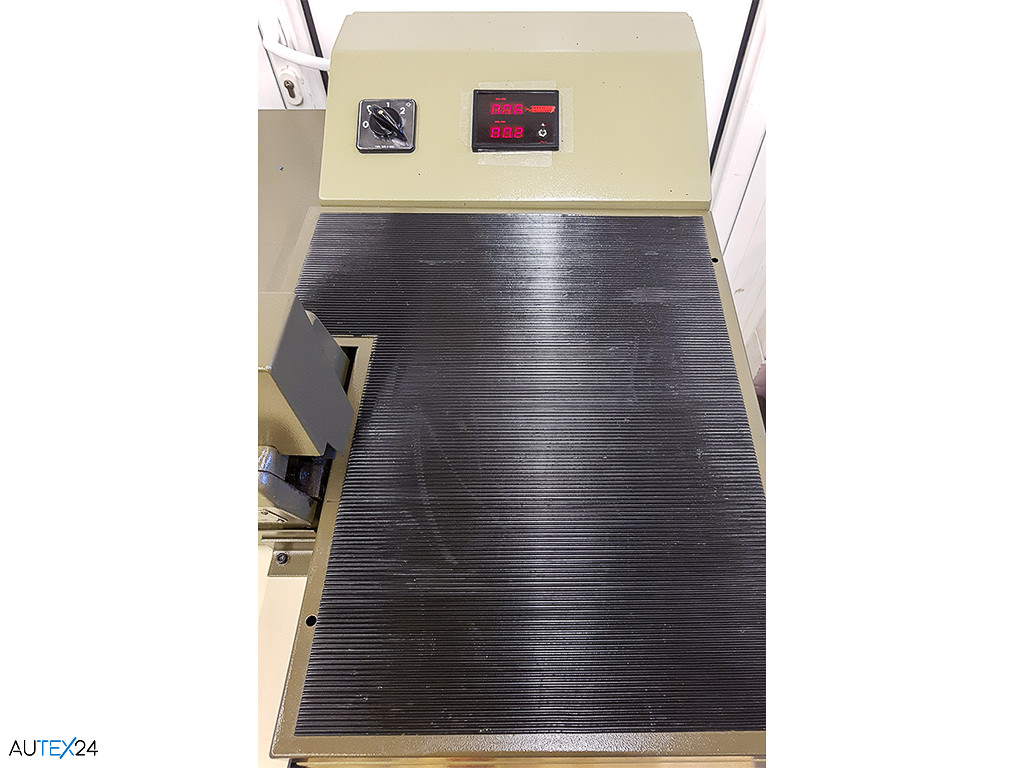

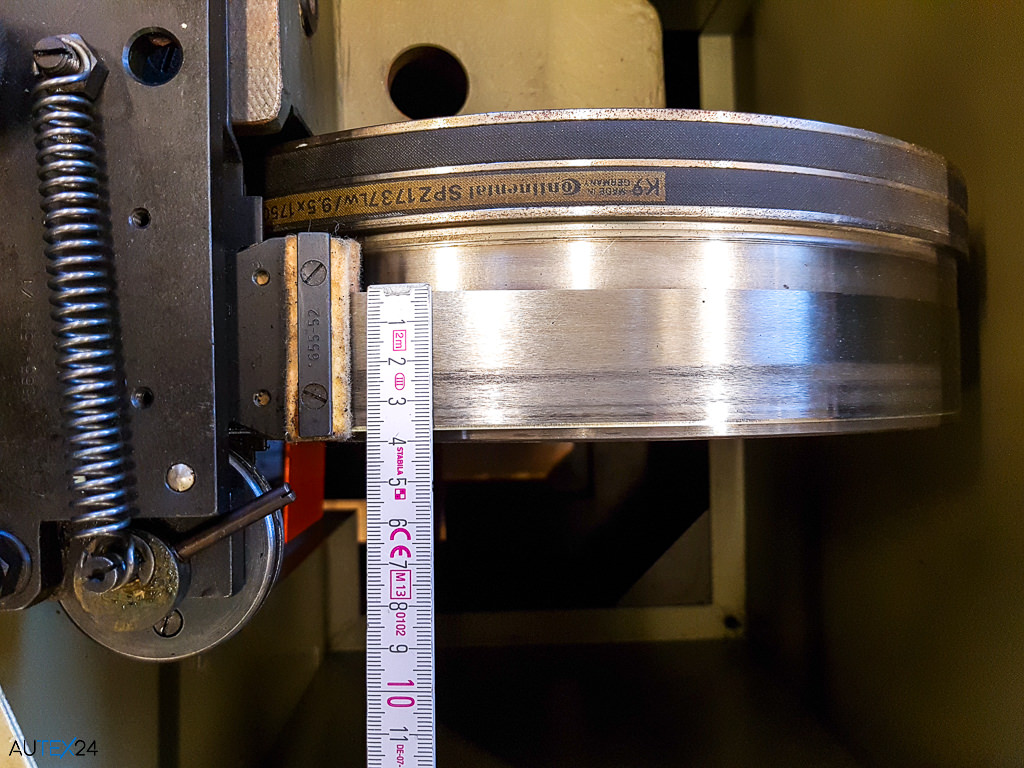

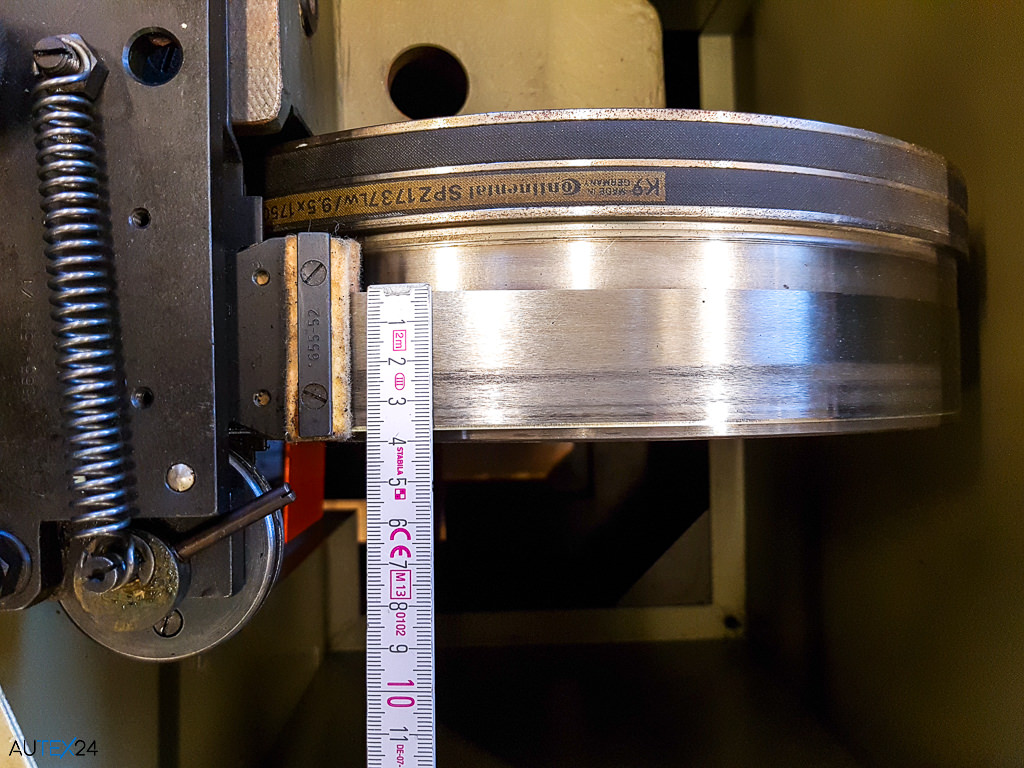

The leather splitting machine is equipped with a driven guide roller. It has a maximum splitting width of 320 mm. Splits from 0.5 - 5 mm are possible with the guide roller. The splitting thickness is set on the easily accessible handwheel with a micrometer scale (1/10 mm graduation).

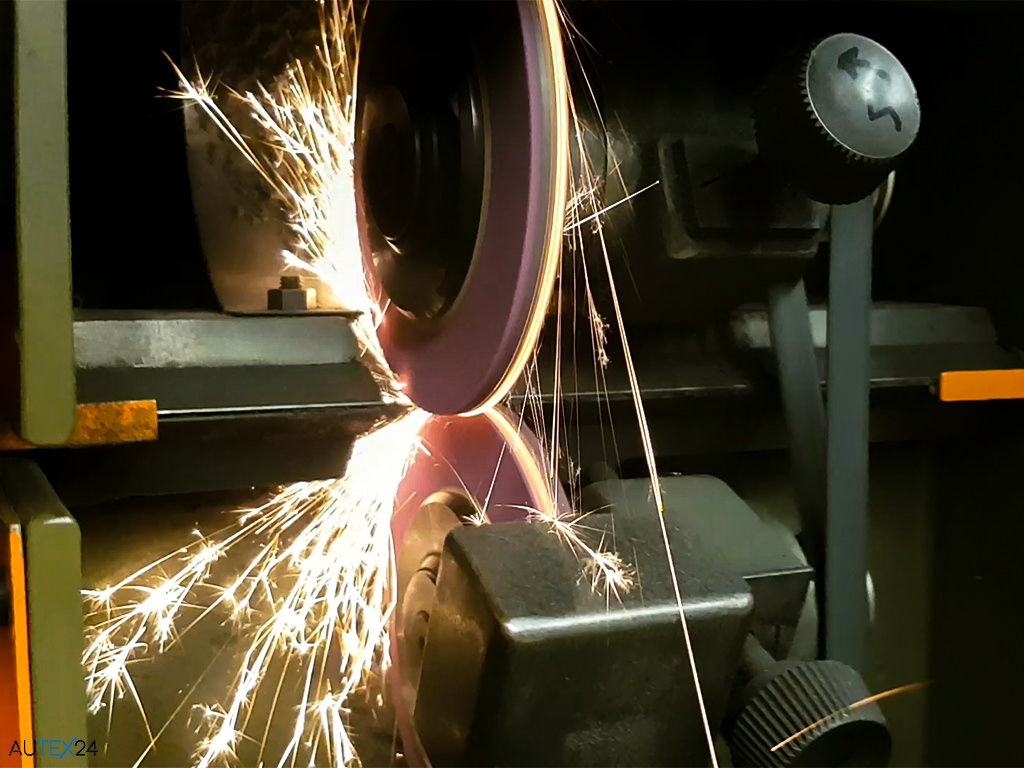

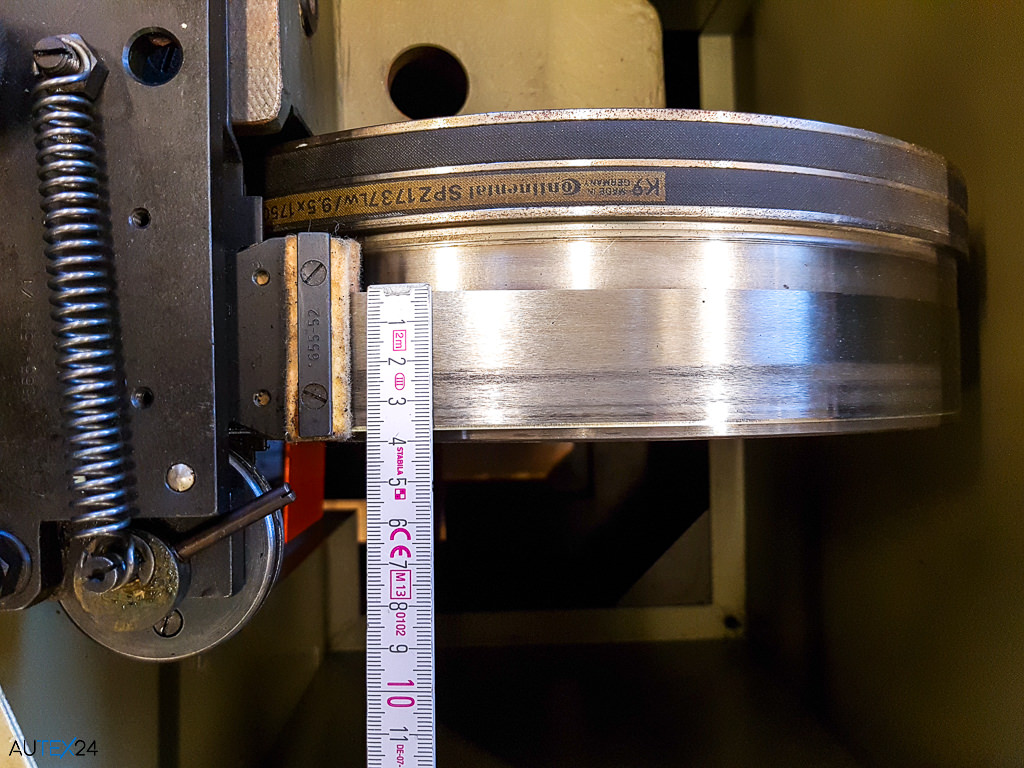

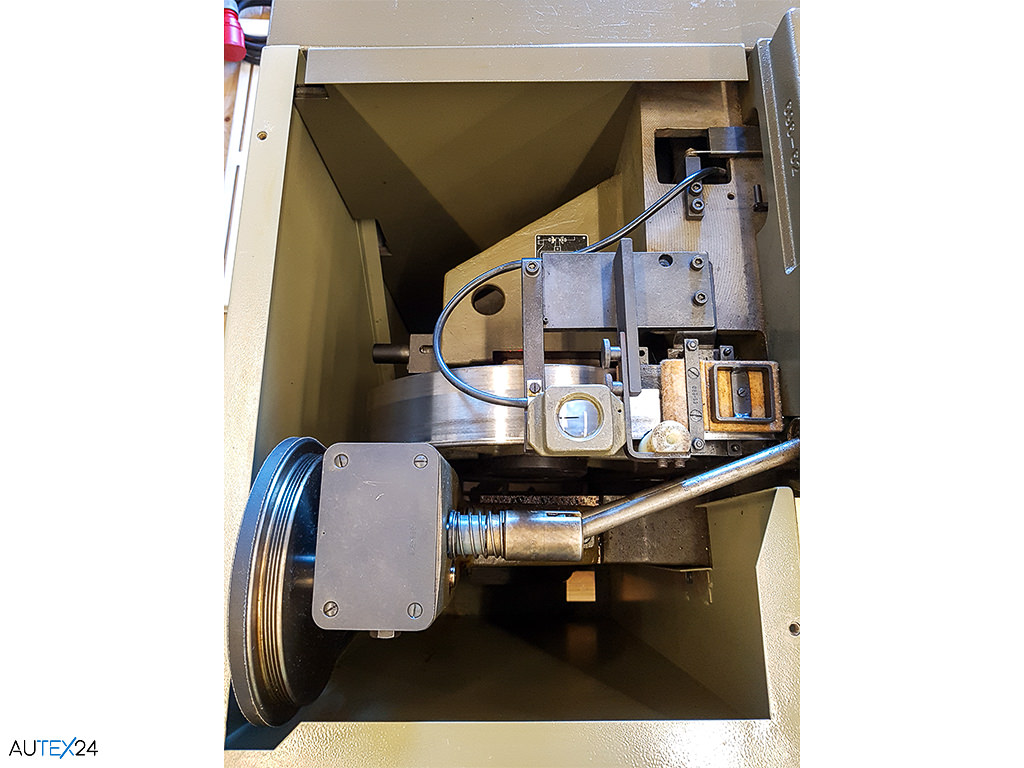

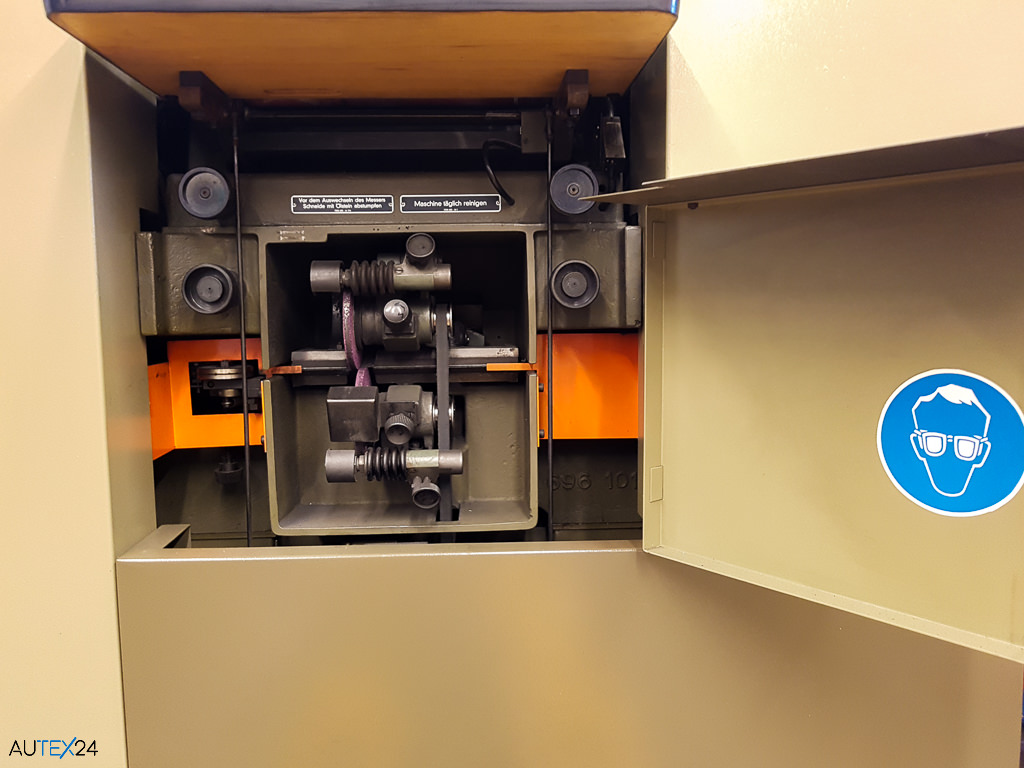

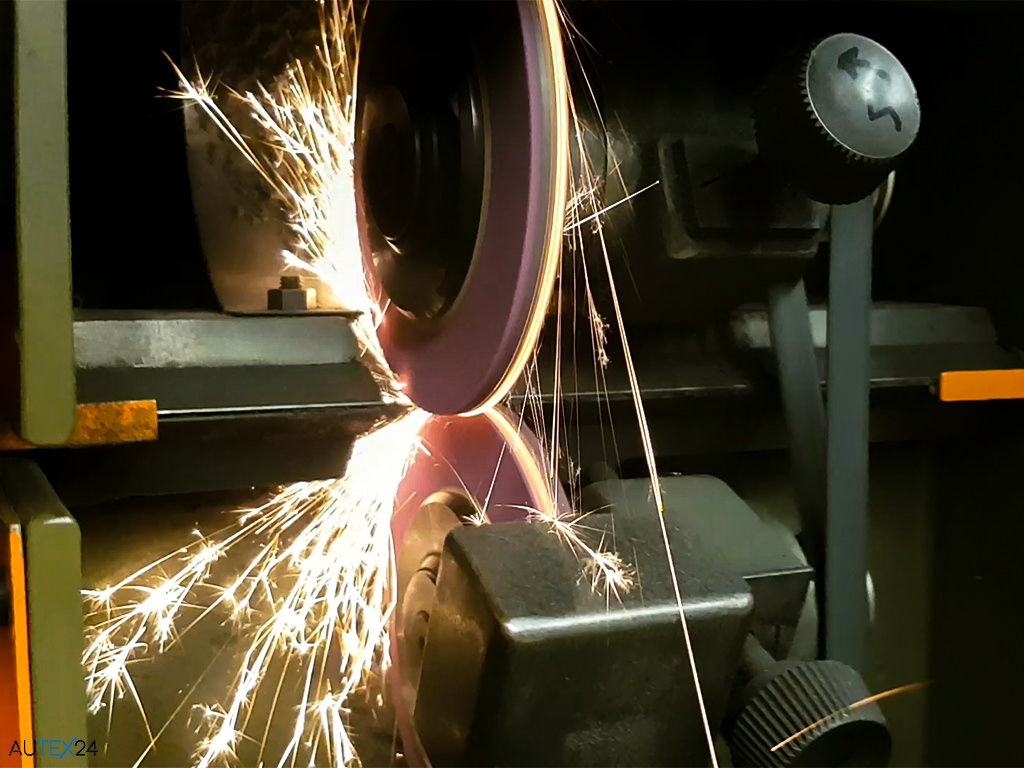

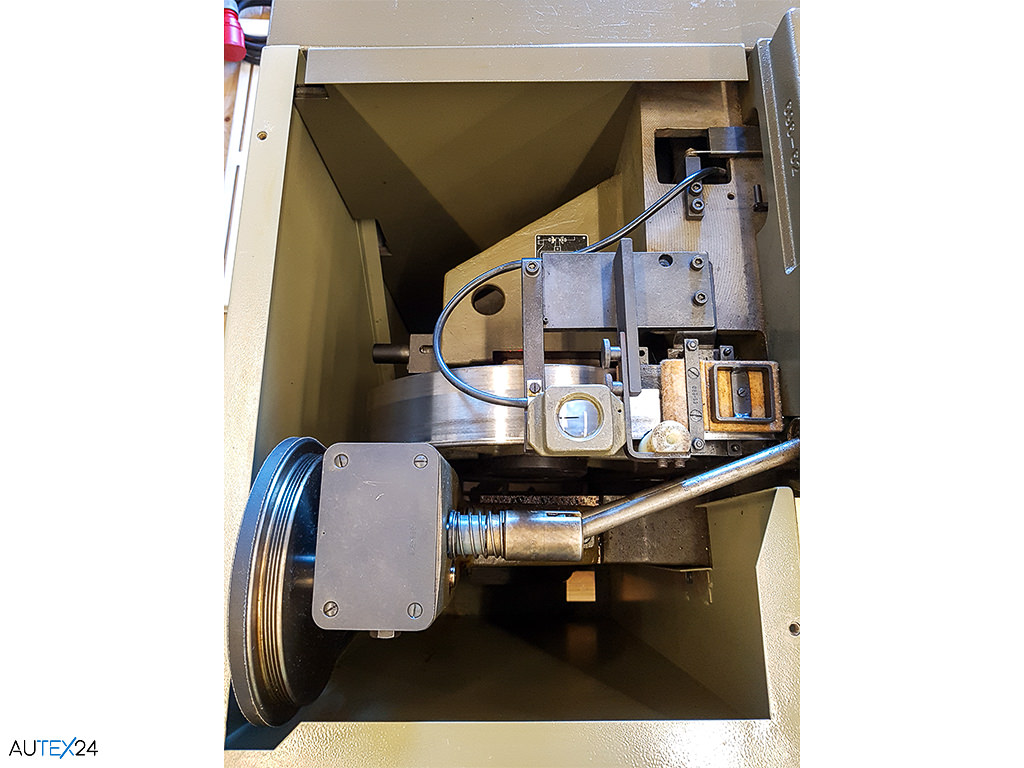

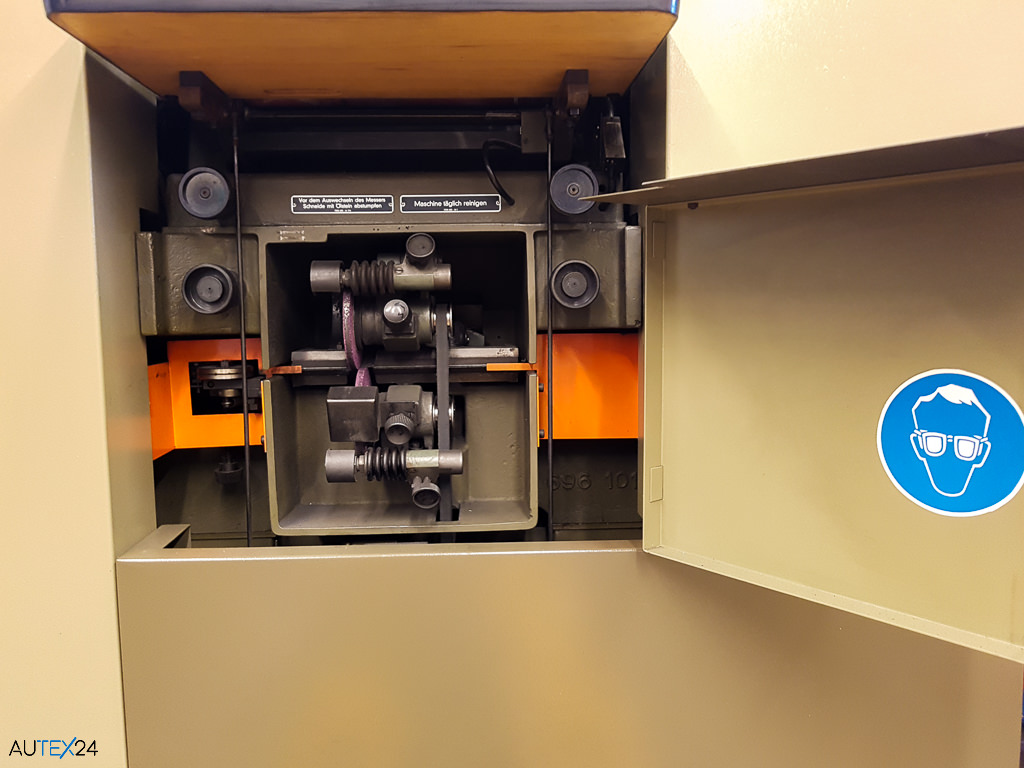

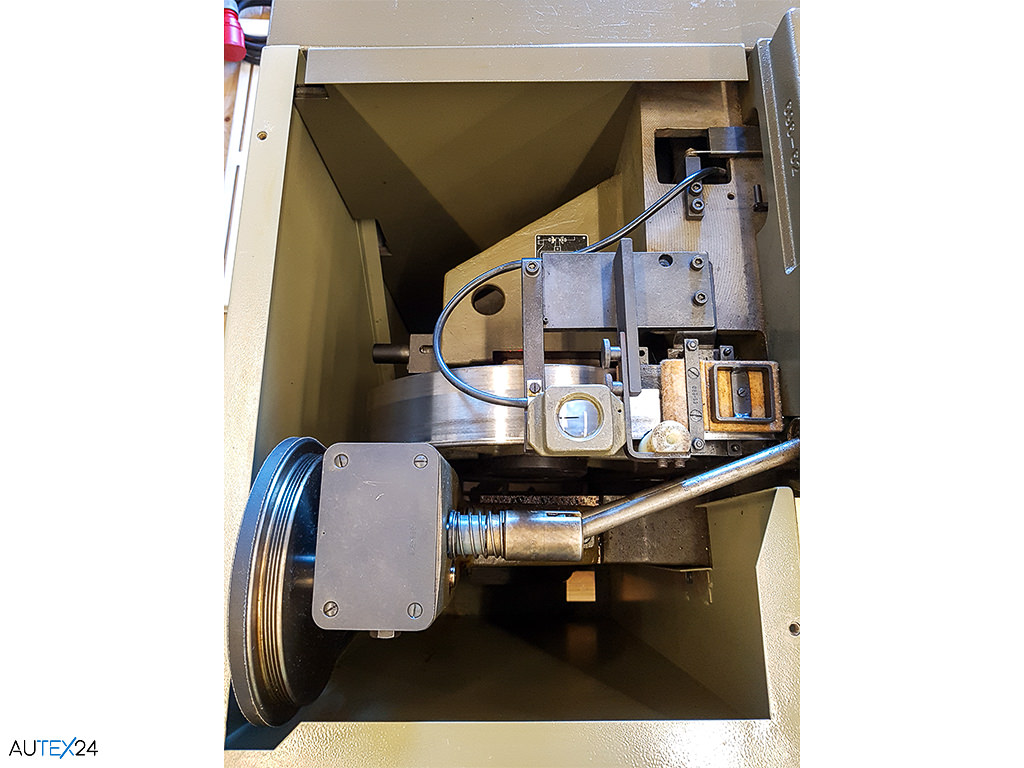

The automatically adjusting knife eliminates the need for manual adjustments and maintenance, ensuring a constant knife cutting position and thus splitting quality at all times. In addition, the built-in automatic spring system maintains a constant and uniform bandknife tension, even when heated.

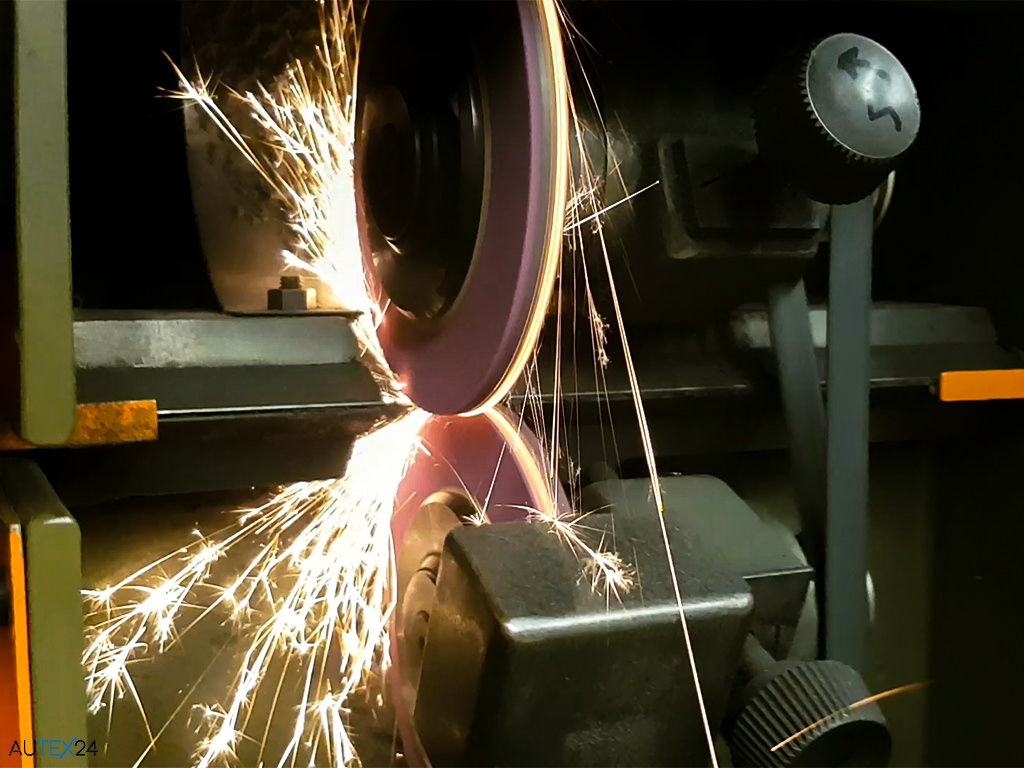

The band knife has a constant cutting speed and thus has maximum cutting force, independent of feed speed and slit material.

The lower elastic feed roller is suitable for both the guide roller and the guide ruler. The contact pressure and the associated feed force are infinitely variable, and four feed speeds can be set.

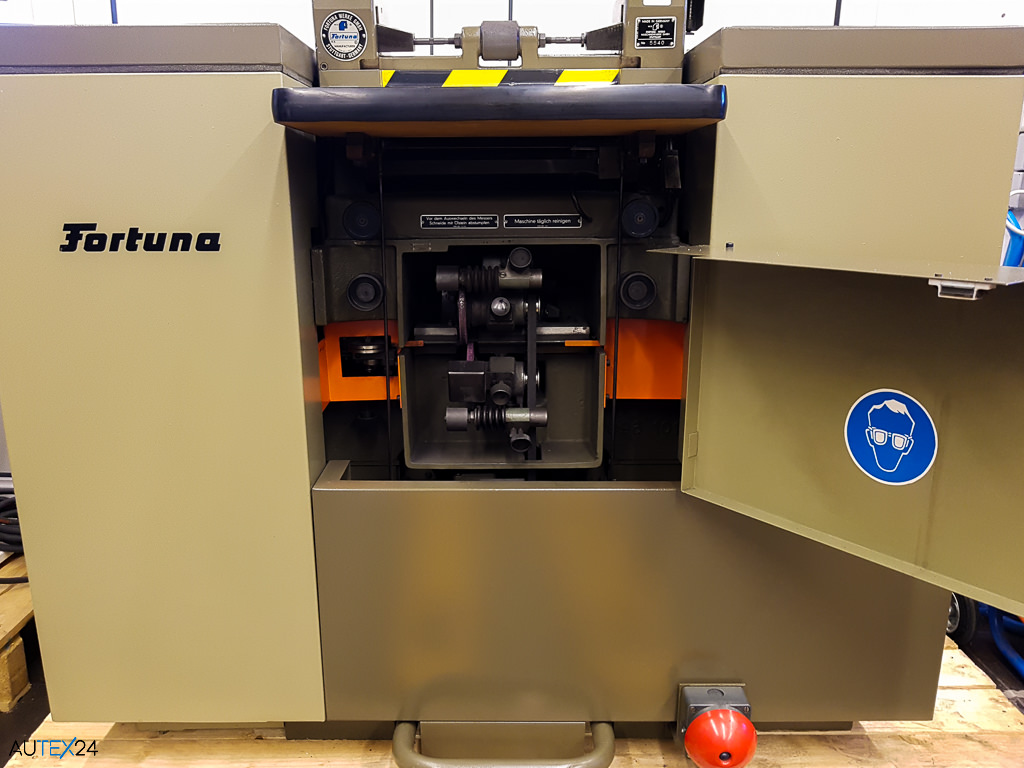

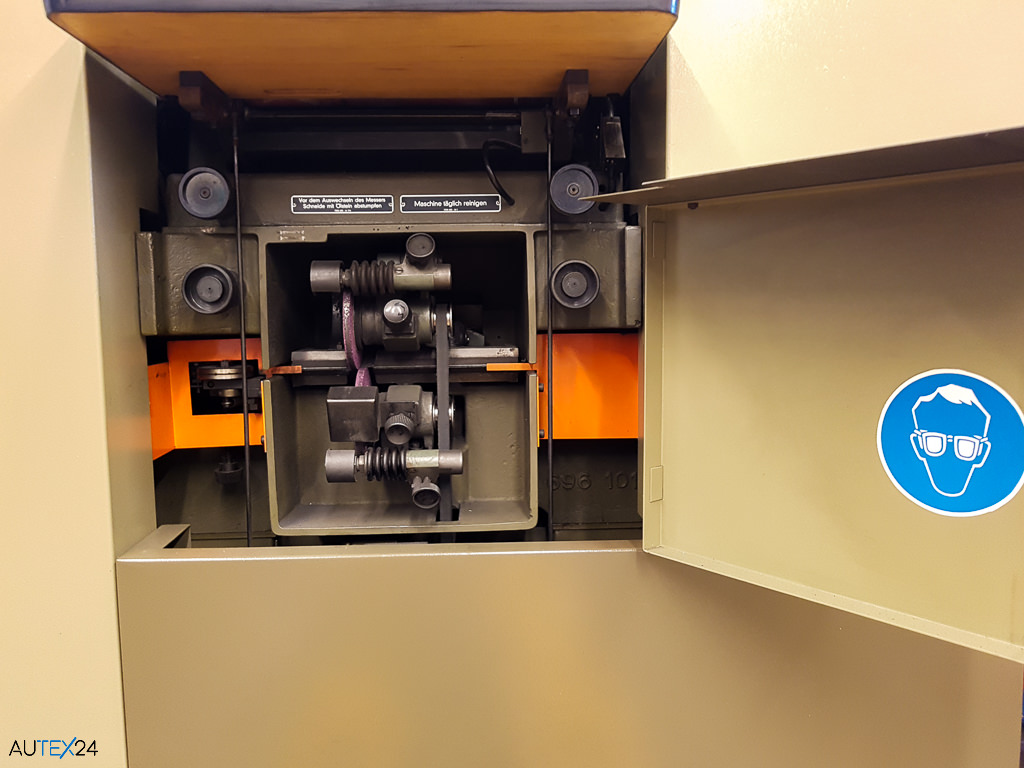

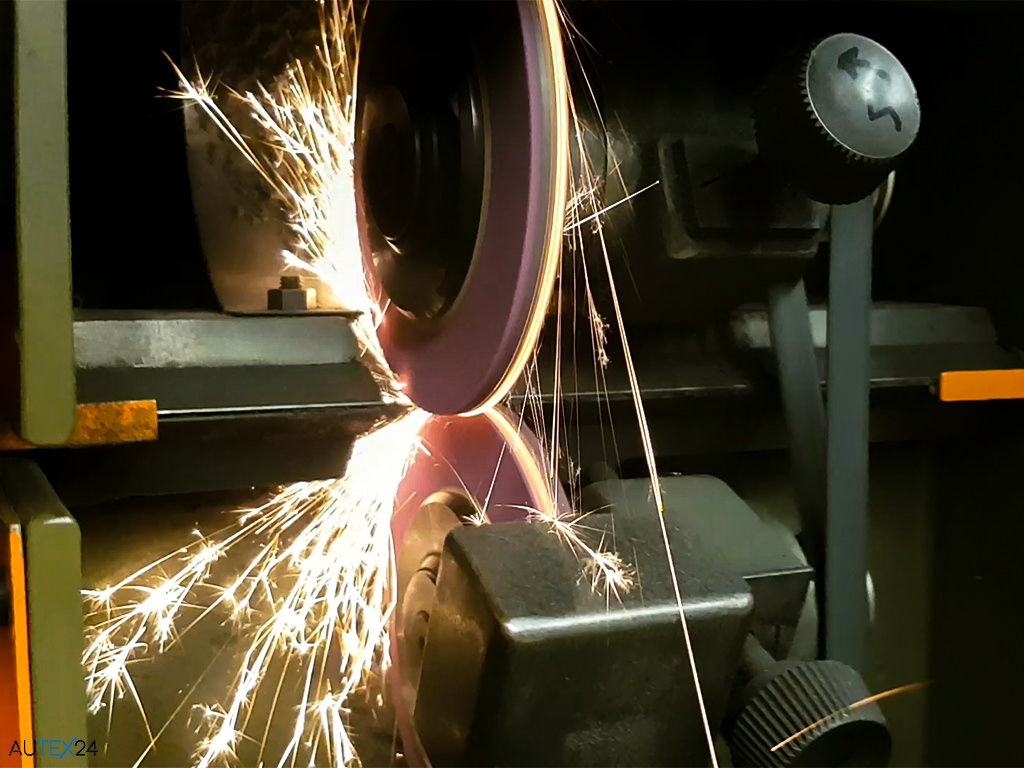

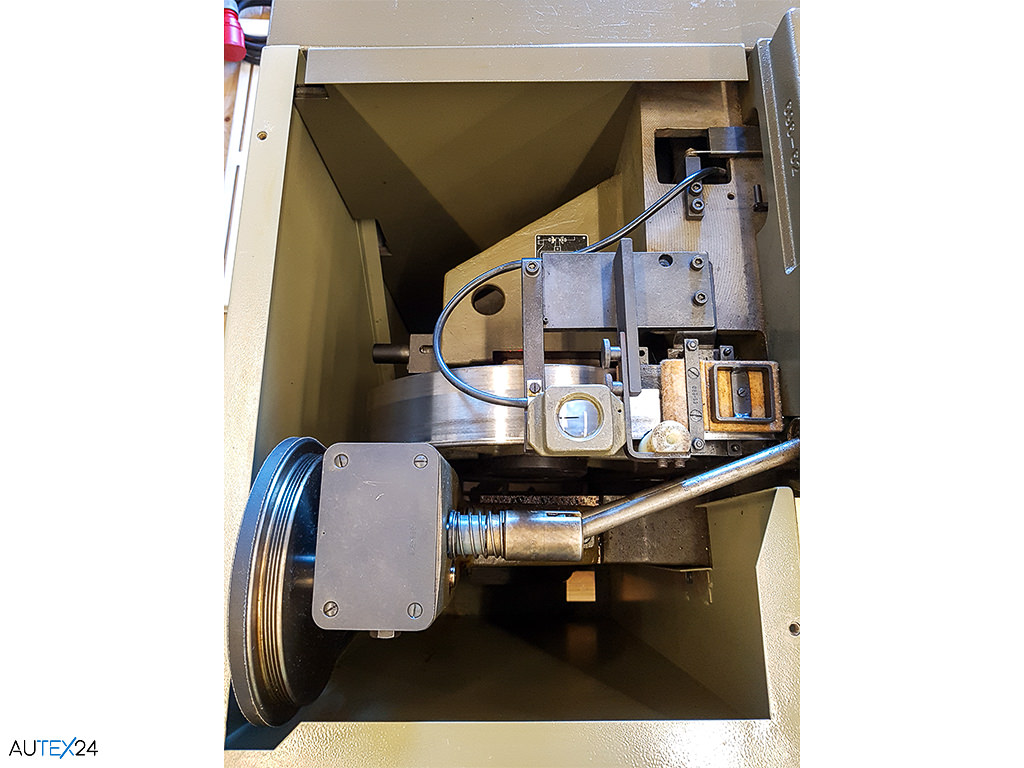

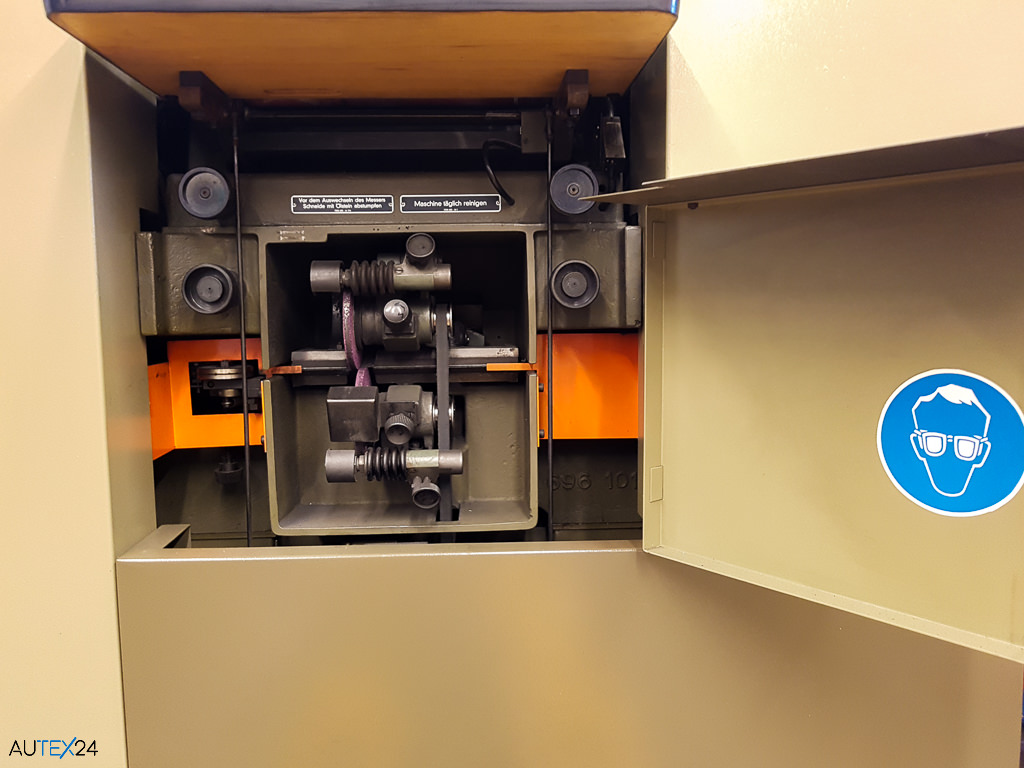

Another feature of the "AV 320″ series, is the integrated grinding device, which always guarantees a clean grind, a perfect knife edge, economical grinding and increased belt knife life. The built-in linking devices are equipped with dust-protected guides and fixed feed sizes for the grinding wheels.

Furthermore, the Fortuna AV 320 leather splitting machine has an automatic chip extraction system with a large chip box and dust filter. This ensures perfect working hygiene, is low-noise and draught-free. Furthermore, no material losses are caused by cutting, which enables trouble-free working.

| Hersteller: | Fortuna |

|---|---|

| Typ: | AV 320 |

| Arbeitsbreite [mm]: | 320 |

| Arbeitshöhe [mm]: | 1000 |

| Spaltdicke min. Lineal [mm]: | 0,1 |

| Spaltdicke min. Rolle [mm]: | 0,5 |

| Durchgang max. [mm]: | 8 |

| Spaltwerkzeug: | Angetriebene Führungsrolle |

| Vorschubwalze: | Elastische Gummiwalze |

| Vorschub: | 4 Stufen |

| Vorschubgeschwindigkeit [m/min]: | 4, 8, 12, 24 |

| Absaugung: | Späne und Staub |

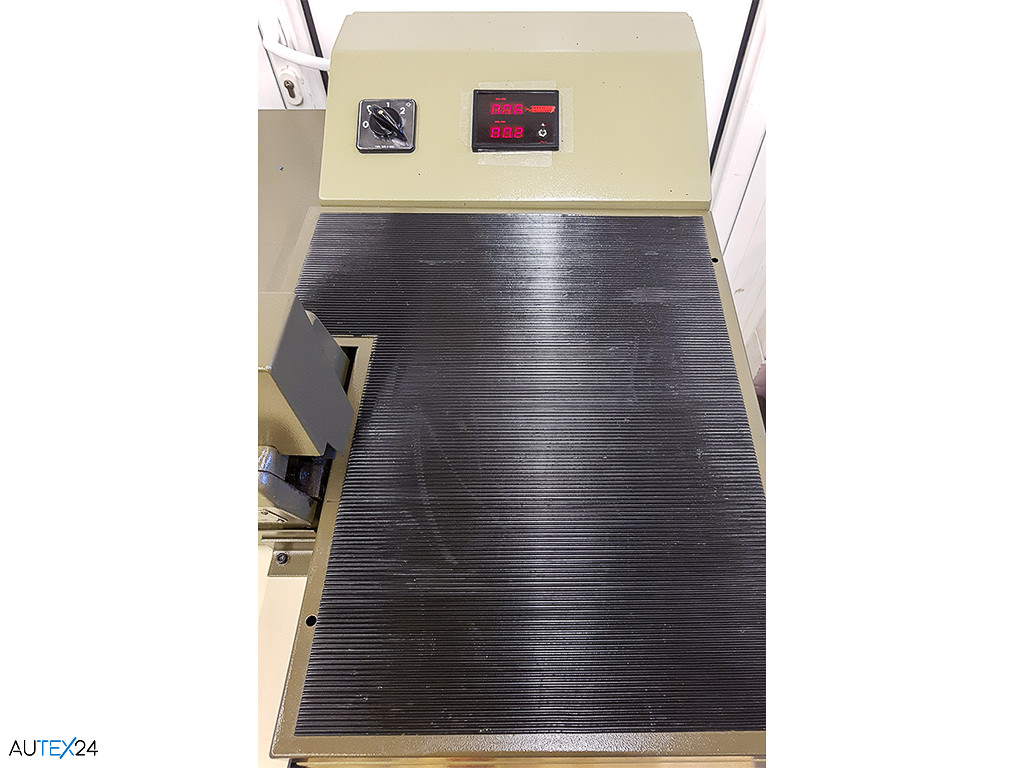

| Digitalanzeige der Spalt- und Spandicke: | Ja |

| Automatisch nachstellendes Messer: | Ja |

| Fingerschutz: | Ja |

| Anschlussspannung: | 400 V Wechselstrom (AC), 3-Phasen, 50 Hz |

| Bemessungsleistung [kW]: | 2,7 |

| Geräuschemission dB [A]: | 78 |

| Abmessungen (Länge x Breite x Höhe) [mm]: | 1300 x 900 x 1200 |

| Nettogewicht [kg]: | 510 |