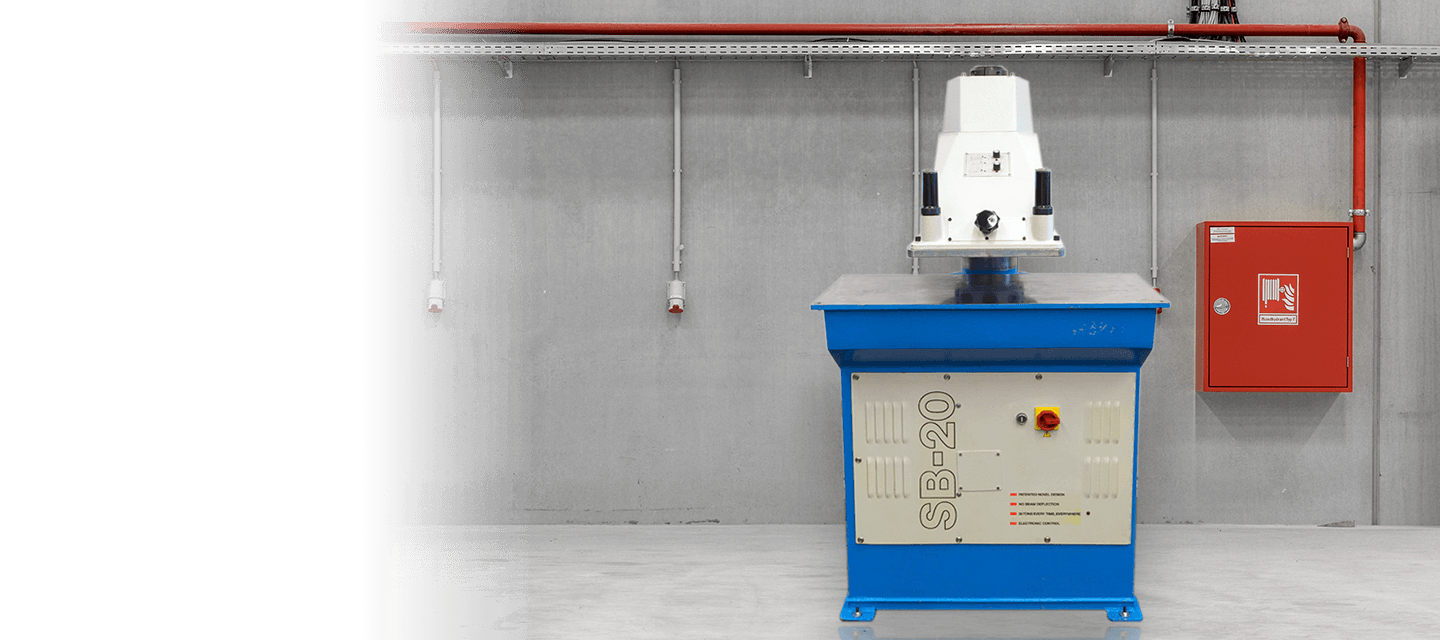

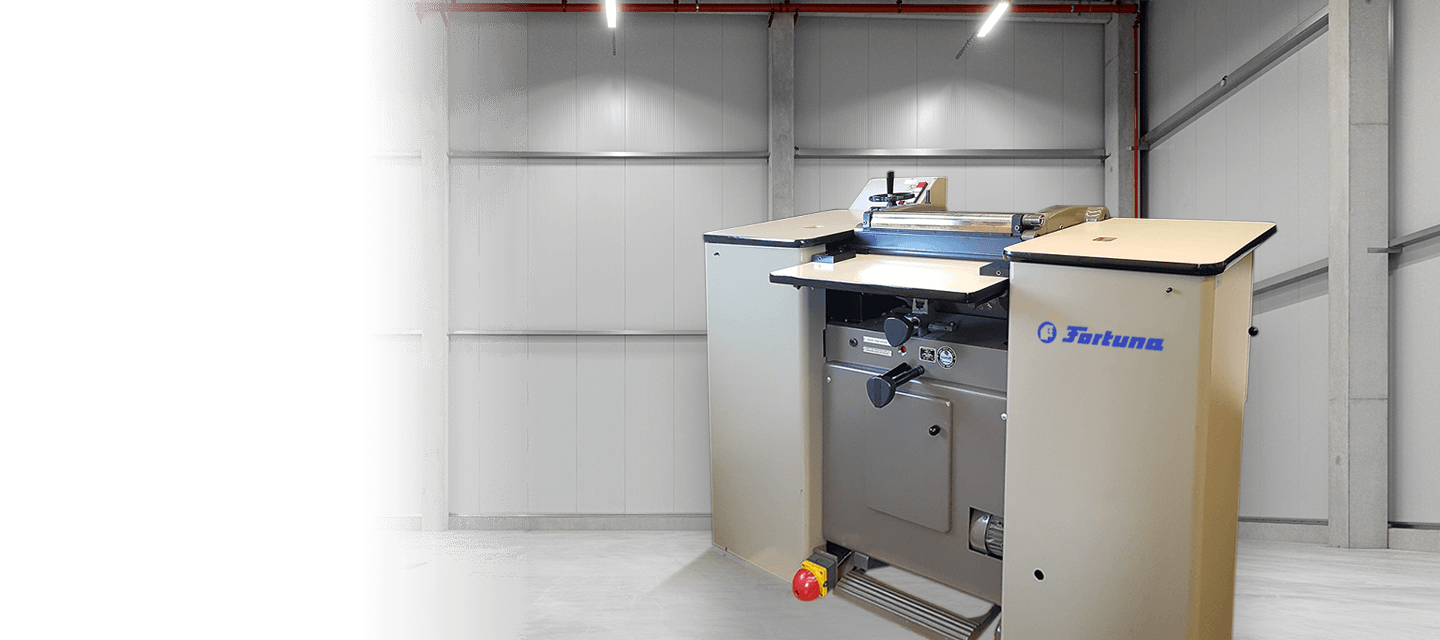

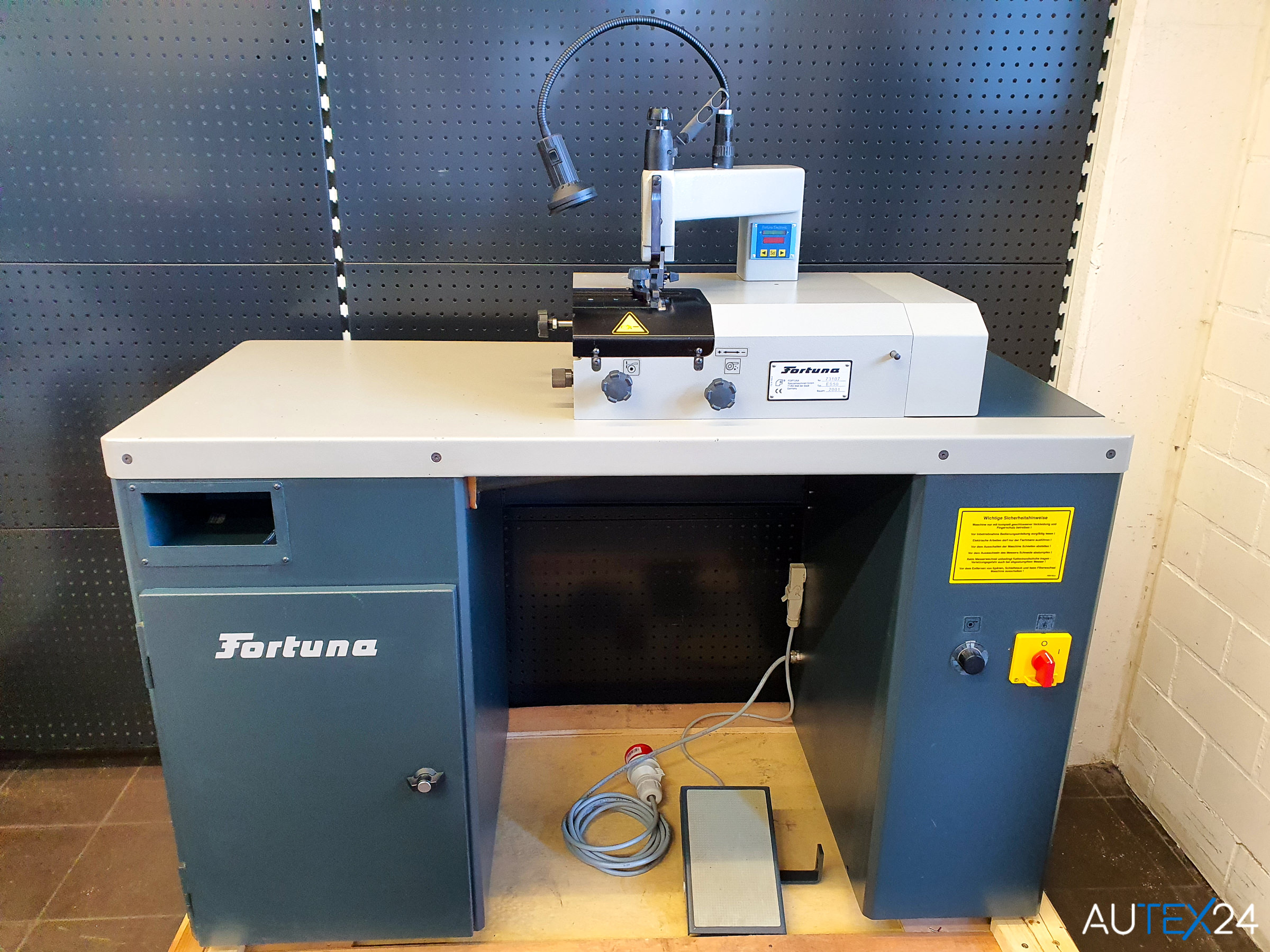

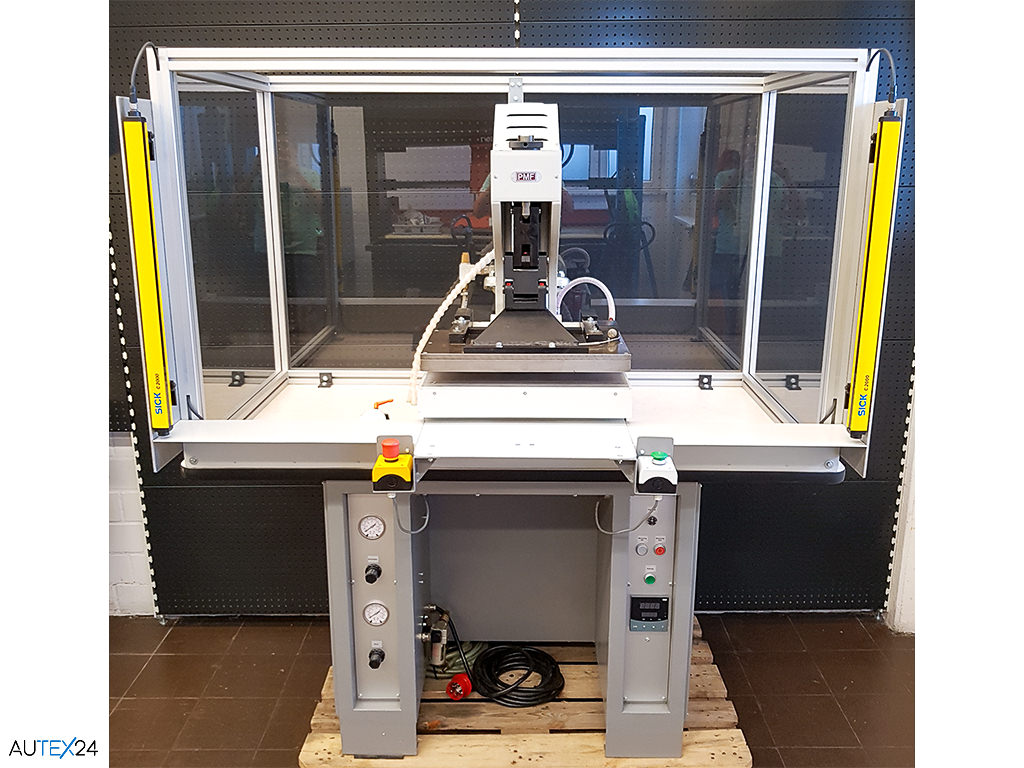

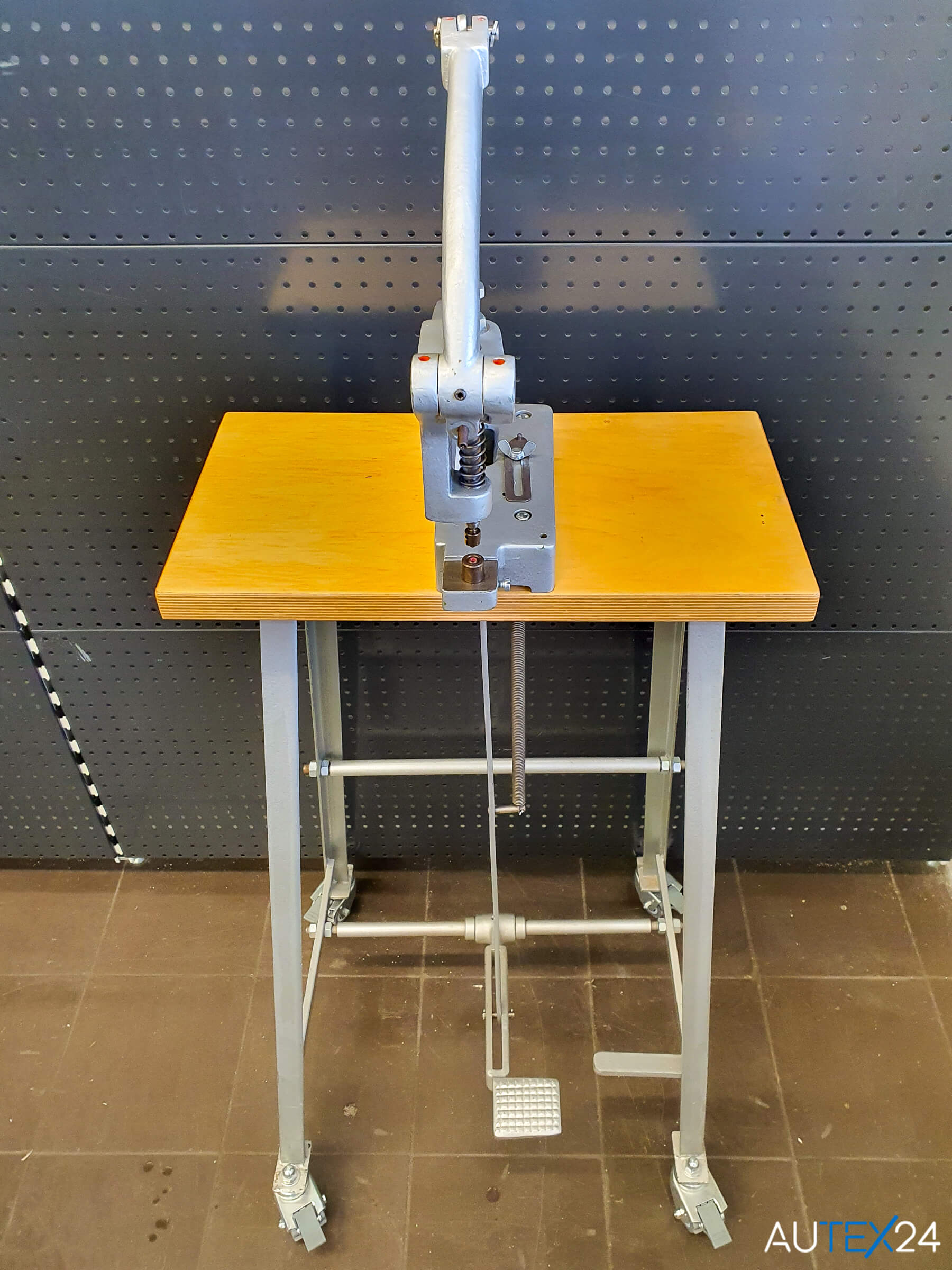

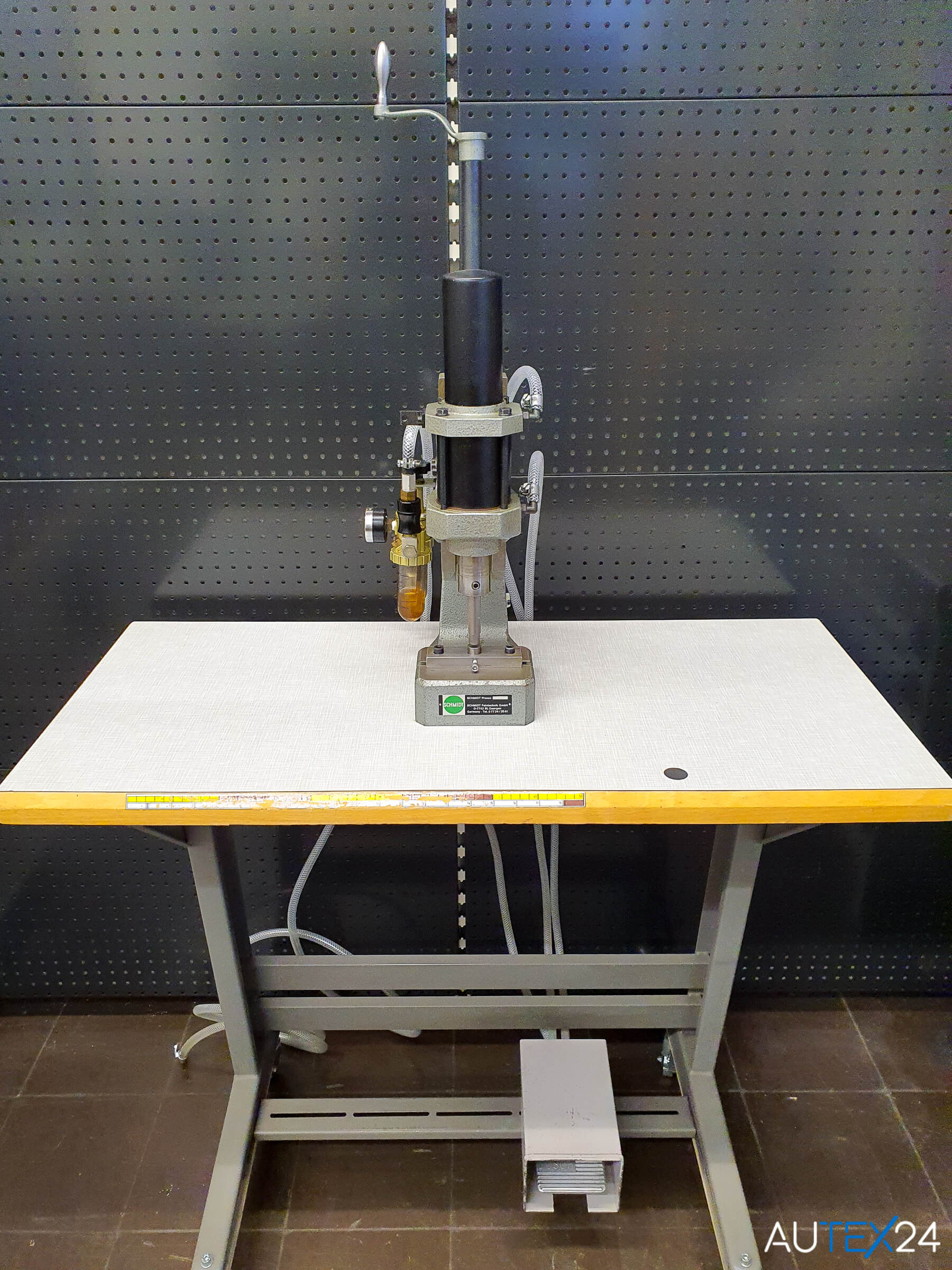

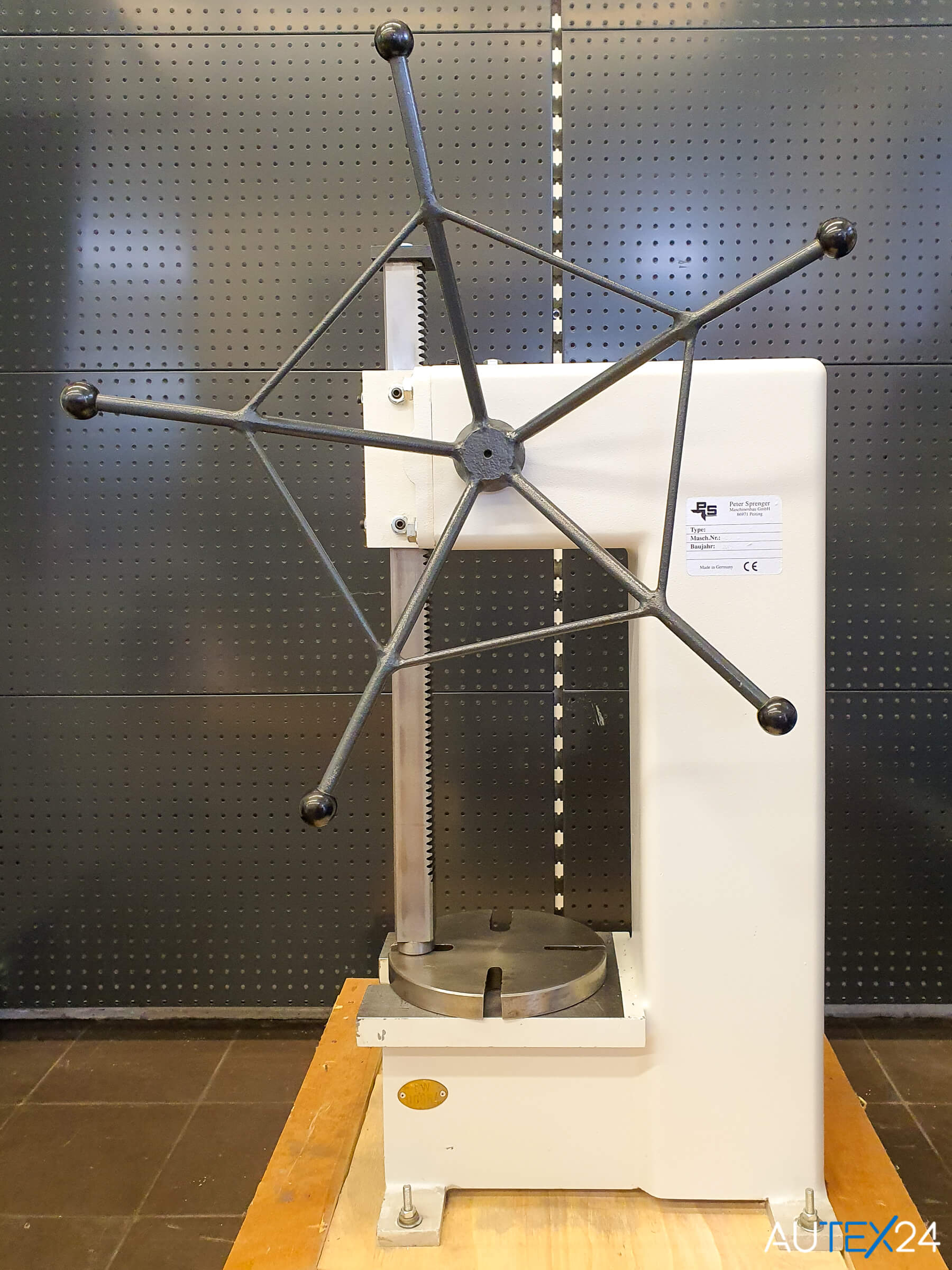

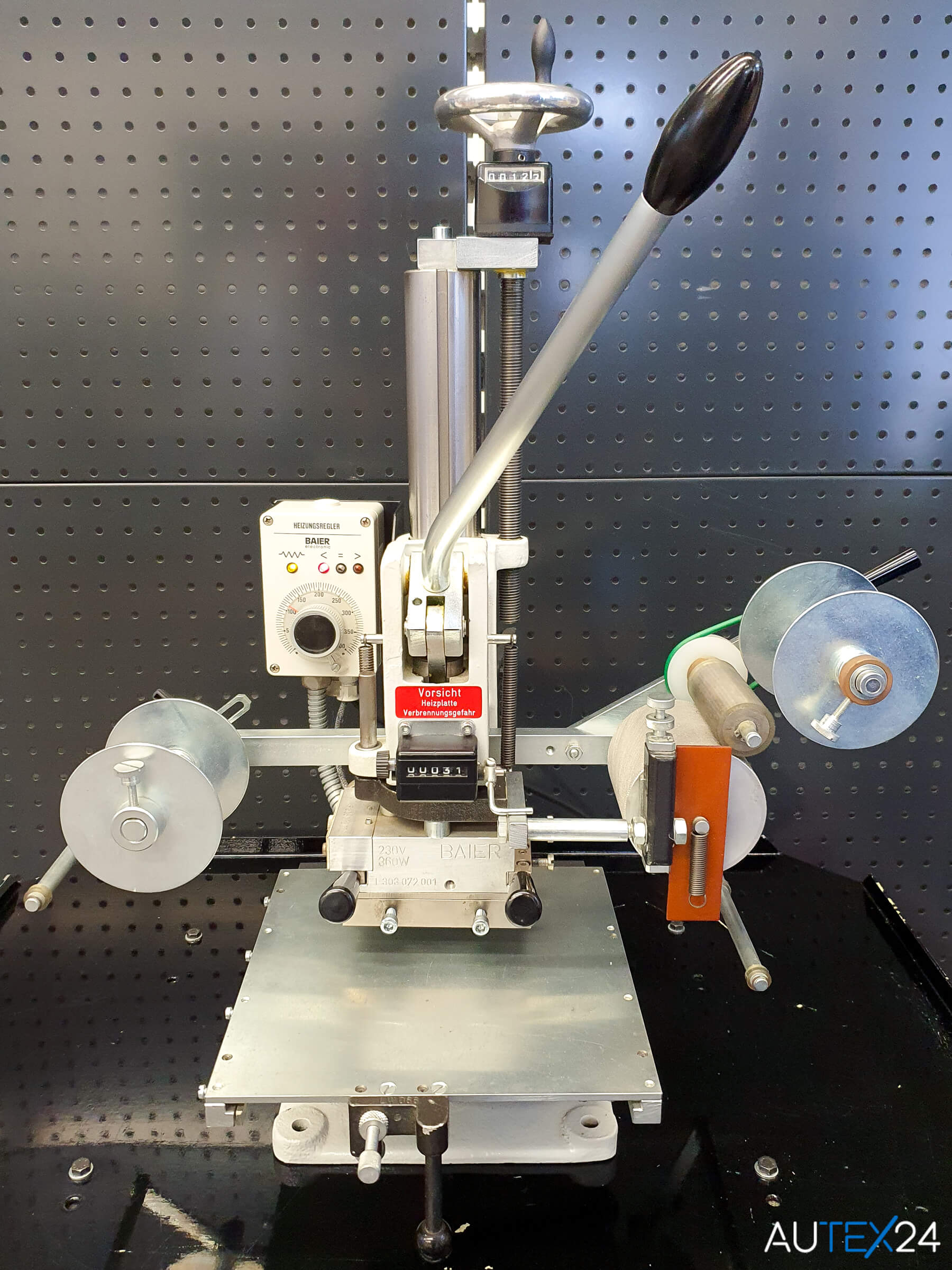

New arrived

Your advantages

Qualitätsmaschinen

Steigerung Ihrer Produktivität und Reduzierung Ihrer Betriebskosten durch hochwertige Gebrauchtmaschinen führender Hersteller.

Sofort verfügbar

Profitieren Sie von sofort verfügbaren Maschinen, um auf Aufträge und Produktionsumstellungen kurzfristig reagieren zu können.

Speditionsversand

Schnelle und sichere Lieferung durch versicherten Speditionsversand ausgeführt von unseren langjährigen Logistikpartnern.

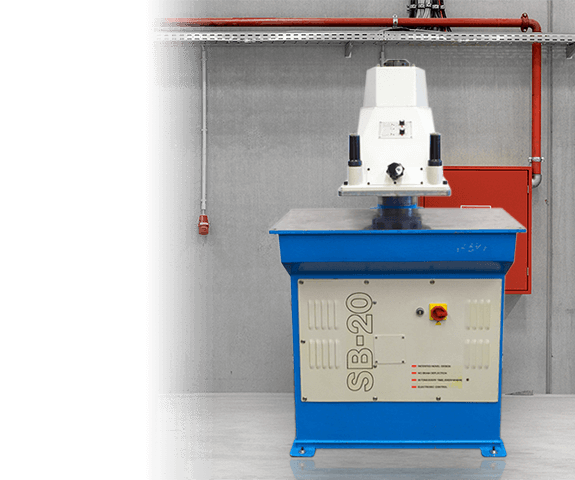

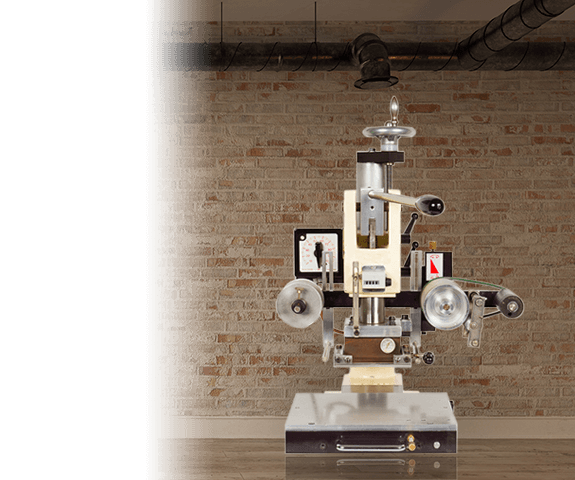

Product videos

Our product videos present our machines from every angle and make even hidden details visible. Main functions, application areas and special features are demonstrated in detail. So you can check in advance whether the visual condition of the selected machine and the quality of the manufactured products will meet your demands and requirements.

Your success is our motivation

We are your experts in the purchase and sale of machines for the leather processing industry. We always realize our projects with the necessary heart and soul and a certain curiosity and are always happy to be able to realize new, exciting projects. For 10 years we have been dealing with our main business and the question: Which machines and tools do our customers need for the high-quality processing of their leather products? We not only rely on the excellent expertise of our long-term business partners, but also test some of the machines we offer ourselves.